Solar panel testing and certification are the processes done for measuring the performance, safety, and quality of solar panels to make sure they meet industry standards and regulatory requirements. These procedures are extremely important for the long-term dependability and trustworthiness of solar energy systems.

Getting a Certification for a solar panel means getting recognized officially by regulatory bodies or independent organizations. It ensures that the panel meets certain quality criteria. This certification is necessary to be compliant with industry standards and be eligible for government incentives or rebates.

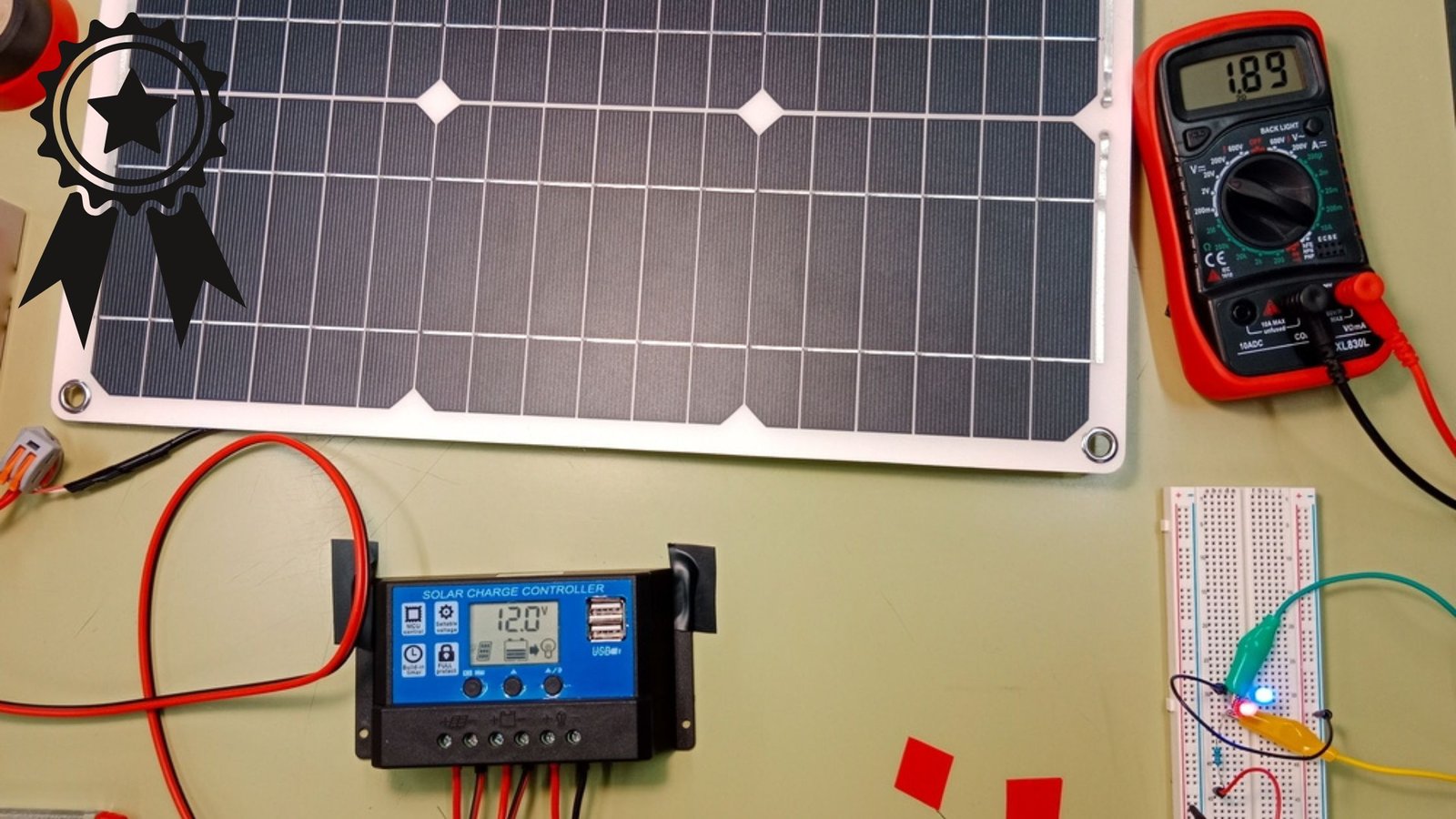

Solar panel testing performs a series of testing procedures like — Performance Testing, Durability Testing, Safety Testing, and Quality Assurance to determine the efficiency, durability, and safety of photovoltaic modules.

It is very important to understand what is International Electrotechnical Commission (IEC), why solar panel testing and certification are Important. Usually, people are concerned and worried thinking about how long the testing and certification process typically takes.

Also, you will get answers to these questions along with the different types of Solar Panel Testing and Certifications that include IEC 61215, IEC 61646, IEC 61701, IEC 61730, IEC 62716, IEC 60068-2-68, Underwriters Laboratories (UL), UL 1703, UL 61730.

Why Are Solar Panel Testing and Certification Important

Solar panel testing and certification are crucial to ensure safety, reliability, and performance. Also, here are the other reasons, such as:

- Quality Assurance makes sure that solar panels meet the standards, of durability, and long-term reliability.

- Safety Check identifies possible dangers such as electricity faults or fire risks, ensuring that solar panels meet safety regulations to protect both installers and the consumers who use them.

- Performance Guarantee Certification confirms whether solar panels are performing as advertised, giving you confidence about their efficiency and reliability.

- Market Access verifies the level of compliance with regulatory standards and makes a pathway to incentives or rebates.

- Consumer Confidence is boosted that they are investing in the right and reliable, high-quality solar energy product.

- Insurance Requirements are the certification to be given as proof of compliance with safety standards, which minimizes solar installation risks.

- Environmental Impact is minimized by solar panel’s contribution to reducing greenhouse gas emissions and helping deal with climate change. You can learn in detail about the environmental impact of solar energy.

The 2 well-known regulatory bodies that issue certificates for solar panels are:

1. The International Electrotechnical Commission (IEC) maintains international standards and certification for many kinds of electrical products, including solar panels. The IEC 61215 and IEC 61730 certifications are well-recognized in the solar industry.

2. Underwriters Laboratories (UL) is an internationally recognized safety certification company that provides testing services for a broad range of products, including solar panels. UL 1703 certification makes sure about the ability to comply with safety standards in North America and other regions.

Types of Solar Panel Testing and Certifications

Solar panel testing includes 3 different types of testing methods to measure the performance, safety, reliability, and quality of photovoltaic modules. Here are some common solar panel tests conducted:

1. Performance Testing:

- Standard Test Conditions (STC): Tests for performance under specified conditions (1000 W/m² solar irradiance, 25 °C temperature) for comparison between various panels.

- Flash Testing: Quickly and easily measures a panel’s current-voltage (I-V) curve to find any possible defects.

- Maximum PowerPoint Tracking (MPPT): Checks the system’s ability to monitor the point of maximum power output under varying conditions.

2. Durability Testing:

- Thermal Cycling: Performs extremely high-temperature fluctuation to test the panel’s capability to function in harsh environments.

- Damp-Heat Testing: Involves exposing the panel to high atmospheric humidity and temperature to test the corrosion and loss of performance.

- UV Exposure: Analyzes the panel’s ability to resist degrading effects from ultraviolet radiation.

3. Safety Testing:

- Electrical Safety: Examines the panel’s ability to handle electrical shock and the possibility of fire risks.

- Mechanical Load Testing: Testing to determine the panel’s capability to adapt to wind and snow conditions.

Therefore, these tests confirm whether the solar panels meet industry standards and provide reliable performance during their lifetime. Furthermore, many countries ask for panels to be certified by independent certifying organizations to meet particular safety and performance criteria.

Here are a few types of Solar Panel Certification that include International Electromechanical Commission (IEC) and Underwriters Laboratories (UL) mentioned as follows.

International Electromechanical Commission (IEC)

The International Electrotechnical Commission (IEC) is a non-profit global organization established in 1906 that has set international standards for electrical technologies and devices, including Solar or Photovoltaic (PV) panels.

IEC focuses mainly on developing and distributing international standards of electrical and electronic systems and devices. For solar panels, the IEC has set certain standards ensuring its performance, safety, and quality that guide manufacturers, installers, and regulators in the industry and also it:

- Develops international standards

- Provides accreditation to testing laboratories

- Promotes the adoption of its standards worldwide

The IEC has various standards established for different types of solar technologies such as IEC 61215, IEC 61646, IEC 61701, IEC 61730, IEC 62716, and IEC 60068-2-68 which are explained in detail as follows.

IEC 61215 (Standard for crystalline silicon terrestrial PV modules)

IEC 61215 is an international standard that sets certain requirements by implementing testing procedures like design qualification and type approval of crystalline silicon photovoltaic (PV) modules. Also, it ensures the durability and performance of the modules during their long-term running in outdoor environments as well.

Although IEC 61215 mainly applies and focuses on crystalline silicon terrestrial flat-plate PV modules, including solid solar panels made from crystalline silicon (the dominant material in the solar industry). However, It doesn’t apply to thin-film modules (covered by IEC 61646) or other flexible modules used in temporary applications.

The importance of IEC 61215 is proven in ensuring the reliability and quality of crystalline silicon PV modules by undergoing many testing procedures. Also, it meets the standard’s requirements. It allows manufacturers to convince consumers that their modules can last longer with good performance even in various outdoor conditions, which will benefit various groups of people:

- Manufacturers can gain market confidence about their products.

- Installers are assured of using trusted modules for their projects.

- Investors make educated decisions based on performance and durability.

- End users benefit from solar energy generation through their PV systems.

IEC 61646 (Standard for Thin-film PV Modules)

IEC 61646 is a standard developed by the International Electrotechnical Commission (IEC) that has laid requirements for design qualification and type approval of terrestrial thin-film photovoltaic (PV) modules. This standard aims to ensure that thin-film PV modules meet specific performance, reliability, and safety criteria for use in solar energy systems.

It applies to all flat-plate thin-film PV modules not covered by the IEC 61215 standard, which focuses on crystalline silicon PV modules. Also, ensures that thin-film PV modules are designed and manufactured to withstand the rigours of long-term outdoor use in various climates.

The IEC 61646 standard is important in promoting the safety, reliability, and performance of thin-film PV modules. Also, it allows manufacturers to guarantee their product’s quality and long-term sustainability, increasing confidence in the technology and encouraging them to adopt thin-film PV technology.

People confuse between these two but there are minute difference between Thin-Film and Crystalline Silicon Solar Panels.

IEC 61701 (Salt Mist Corrosion Testing)

The IEC 61701 test verifies the capability of solar panels to resist corrosion caused by salt mist containing chloride (NaCl, MgCl2, etc.). This is very influential for panels in coastal regions or areas with high salt spray exposure.

Under the IEC 61701, the Solar Panel undergoes a few tests, including exposure to a controlled salt mist environment at a particular temperature and duration. Also, it performs analysis of any possible faults in:

- Corrosion

- Power output

- Bypass diode functionality

Following that, it undergoes multiple electrical and visual inspections to check for any deformation or corrosion damage.

IEC 61701 Certification is important to ensure the panel’s long-term reliability and safety in difficult coastal environments. With this certification, customers will have peace of mind and manufacturers can build trust in their products.

IEC 61730 (Standard for Pv Module Safety)

This test of the IEC 61730 standard is to determine a solar panel’s safe build quality and functionality. Also, It makes sure that the panel meets safety standards in terms of electrical, mechanical, and fire.

Under the IEC 61730, the Solar Panel undergoes a few tests by performing the analysis of:

- Electrical leakage

- Insulation resistance

- Mechanical stress

- Endurance

- Fire resistance evaluations

IEC 61730 certification is very important as it assures that the panel complies with international safety regulations and prevents possible accidents by ensuring safe operation.

IEC 62716 (Ammonia Corrosion Testing of Photovoltaic (PV) Modules)

This IEC 62716 test measures a solar panel’s ability to resist damage caused due to ammonia exposure. It becomes crucial for panels especially installed near farms, waste disposal sites, or areas with potential ammonia emissions.

Under the IEC 62716, the Solar Panel undergoes tests including exposure to safe levels of ammonia gas for a certain period. Later on, its electronic performance and physical durability are examined for any indications of corrosion or declined performance.

IEC 62716 certification becomes important, ensuring the panel’s ability to sustain exposure to ammonia in various environments and avoiding performance issues and unexpected failures.

IEC 60068-2-68 (Blowing Sand Resistance Testing)

This test of IEC 60068-2-68 is done to determine a solar panel’s withstanding ability to abrasion and damage caused by blowing sand, which is particularly useful for desert or water-limited environments.

Under the IEC 60068-2-68, the Solar Panel undergoes tests where the panel is repeatedly exposed to a fixed stream of sand particles with defined size and velocity, simulating windblown sand conditions. Afterwards, its visual integrity, electrical performance, and mechanical strength are evaluated for any damage.

IEC 60068-2-68 certification is very important to verify that the panel can adapt to extremely desert environments, avoiding sand-induced wear and tear that could negatively affect its performance as well as lifespan.

Underwriters Laboratories (UL)

Underwriters Laboratories (UL) is a global independent safety science company, established in 1894. It is one of the oldest and largest independent testing laboratories in the United States, which employs over 15,000 people across 40 countries.

UL implements safety standards for a vast range of products and services. Testing and certifying products are their key focus, ensuring to meet standards in terms of safety and sustainability.

The Underwriters Laboratories — UL standards are based on the National Electrical Code (NEC) and Model Building Codes that define safety requirements for electrical installations and design practices.

By complying with UL standards, manufacturers, and builders can confidently guarantee that their products adhere to safety regulations.

UL 1703 (Standard for Flat-plate Photovoltaic Modules and Panels)

The UL 1703 test is a safety certification standard used in the North American market for flat-plate photovoltaic panels and modules. Also, it makes sure that these modules follow specified safety requirements in terms of electrical, mechanical, and fire.

Solar panels undergo thorough and perfect testing under UL 1703, which includes:

- Electrical testing- Verifies insulation and electrical arc fault protection.

- Mechanical testing- Checks resistance wind or snow load.

- Fire testing- Measures flame spread and fire resistance.

- Environmental testing- Determines performance in high temperatures and UV exposure.

UL 1703 certification is important to show solar panels’ compliance with safety regulations, making them eligible for installation. With this certification, both the installer and consumers can have peace of mind ensuring safety standards.

UL 61730: Photovoltaic Module Safety Qualification

UL 61730 is a global international safety standard for photovoltaic modules, that regulates the electrical, mechanical, and fire safety of solar panels across the global markets.

There are several advantages of UL 61730 in comparison to the UL 1703 and IEC 61730:

- It makes the process simpler for manufacturers to reach both the US and international markets with a single certification.

- UL 61730 brings together the latest advancements and new technologies that are not covered under UL 1703.

- Strict safety requirements compared to UL 1703, leading to very safer solar panels.

UL 61730 certification is very important to guarantee compliance with both US and international safety regulations. Therefore, it makes modules globally recognized and supports them in getting accepted in the worldwide market. Especially very important for manufacturers who are exporting solar panels or focusing on international projects.

Here are the UL 61730 benefits that include:

- Improved market access in both domestic and international markets.

- Advanced safety compliance to strict requirements.

- Global recognition and higher trust from clients and customers.

How Long Does the Solar Panel Testing and Certification Process Typically Take?

The duration of the testing and certification process can fluctuate greatly based on these factors, including

- Product or Service complexity that is being tested.

- Particular certification requirements.

- The testing laboratory’s capacity and workload.

Also, depend on the different phases of testing and their average timeframes:

Pre-testing: 1–2 weeks

- Preparing the product or service for testing

- Documentation review

- Test plan development

- Setting up the testing environment

Testing: can vary at times (Most Time-Consuming Phase)

- Running Tests to assess functionality

- Performance test

- Safety test

- compliance with relevant standards

Analysis and reporting: 1–2 weeks

- Comprehensive report generated

- Detailing identified issues

Corrective action and retesting: can vary at times

- Product corrections (if any issues are found)

- Re-testing based on the requirement

Certification review and issuance: 2–4 weeks

- Checks all requirements are met

- Certification body reviews the application and documentation

- Issuing the certificate

Therefore, the entire testing and certification process can depend on the above factors and exact time cannot be specified as it can be somewhere between a few weeks to several months, depending on the circumstances.

Ray is an avid reader and writer with over 25 years of experience serving various domestic and multinational private and public energy companies in the USA.