Solar energy is the sun’s radiation converted into thermal or electrical energy through various technologies. A solar panel is a collection of PV cells that convert sunlight to produce electricity.

There are four important types of solar panels —Monocrystalline, Polycrystalline, PERC and thin film. Under the thin film solar panels, you can find these four different categories — Amorphous Silicon (a-Si), Cadmium Telluride (CdTe), Copper Indium Gallium Selenide (CIGS) and Organic Photovoltaic Cells (OPV).

CIGS solar cells are a type of thin-film solar cells that convert sunlight into electricity. The NREL introduced gallium by integrating it with the CIS solar cell, thereby creating the first CIGS solar cell in 1995.

To understand the science as well as environmental and health concerns of CIGS solar panels, you need to know its applications, the manufacturing process and the complexities resulting in certain advantages and disadvantages. Several factors like absorption, flexibility, material scarcity and production costs make them different from other solar panels.

The science of Copper indium gallium selenide (CIGS) solar cells

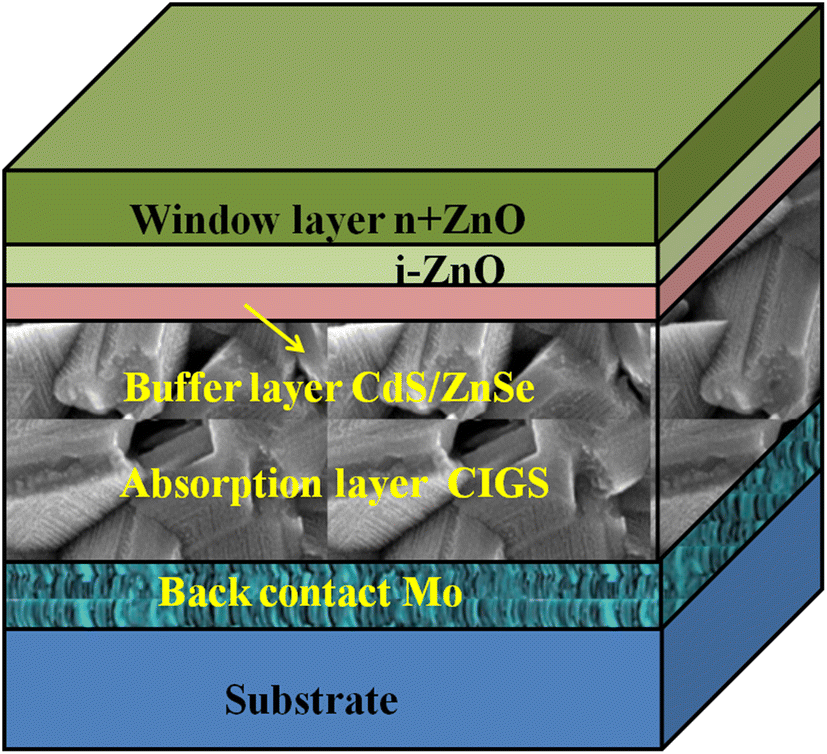

Image Source: ResearchGate.net

The science of CIGS solar cells can be understood by breaking down its structure which consists of several layers such as:

- Substrate Glass of 1 mm to 3 mm thickness to withstand subsequent deposits.

- The back contact layer, made of Molybdenum (Mo) with 500 nm thickness, reflects the unabsorbed light to the CIGS absorber layer.

- A Buffer layer made of Cadmium Sulphide (CdS) undergoes a chemical deposition method.

- The Window layer comprises an inner zinc oxide layer (i-ZnO) which is overlaid above the buffer layer. Additionally, a thick aluminium (Al) doped ZnO layer along with the i-ZnO protects the buffer and absorber layer.

A window layer and buffer layer form a p-n junction with CIGS layers to separate the electron-hole pairs, thereby enhancing the performance.

The combination of elements like Copper, Indium, Gallium, and Selenium tunes the bandgap. These four elements when paired form a three-dimensional bonded semiconductor, with a quartz crystal structure.

They are deposited on plastic or glass with electrodes on the front and back sides to receive electricity.

The variable bandgap of CIGS with a range of 1.02 eV to 1.69 eV enhances the absorption efficiency of solar energy. It can be achieved by altering the basic structure of CIGS material. In other words, the specified bandgap can be achieved by adjusting the change in the ratio of gallium and indium.

In basic terms, a Bandgap is the energy difference between the CIGS absorber layer of the conduction band and valence bands.

The Manufacturing Process

- Glass

- A polymer (also known as polyimide)

- Titanium metal foil

- Stainless steel, or a similar material.

These materials are used to improve the flexibility, transparency, and resistivity of the layer where other elements can be placed on its top. Additionally, you can learn about how solar panels are made to get a better idea about the manufacturing process of panels.

Various techniques are used to deposit the CIGS layer onto the substrate, such as:

1. In Chemical Bath Deposition (a non-vacuum process), a substrate is immersed in a solution containing the preparatory materials which get hydrolysed, heated, and stirred before they get deposited on the CIGS layer.

2. Electrodeposition involves a deposition voltage of −1.5 V applied between the substrate and an electrode in a precursor solution. Due to the electric field, the precursors get deposited onto the substrate.

3. In Atomic Layer Deposition, the process of the precursor deposition into the chamber containing the substrate gets divided into two or more half-reactions that are self-limited to the thickness and composition of the CIGS layer.

4. Physical Vapour Deposition is a vacuum process that involves the preparatory materials undergoing the conversion of vaporization to condensation onto the substrate to form a CIGS layer.

5. Ultrasonic Spray Pyrolysis (USP) is a non-vacuum process developed as an alternative to buffer-layer. The process includes the precursors atomized into a fine spray which can evaporate the solvent by separating the CIGS layer.

6. In an Ionic Layer Gas Atomic Reaction (ILGAR), the precursors are introduced in the form of thin ions.

Each technique has different costs and efficiencies. Typically, the vacuum process can be more expensive than a non-vacuum process due to its higher efficiency.

Advantages of CIGS solar cells

Here are the advantages of CIGS solar cells you need to know in detail:

- High Absorption

- Flexibility

- Lower Production Costs

High Absorption

CIGS solar cells have a higher absorption coefficient greater than 105/cm for 1.5 eV and photons of higher energy. The higher absorption coefficient allows CIGS to capture 90% light with only about 1 µm layer thickness. Mainly, the CIGS has a direct bandgap which can be controlled between 1.0 and 1.7 eV. It results in absorbing a broad spectrum of sunlight more effectively and better conversion into electricity than other photovoltaic materials.

Flexibility

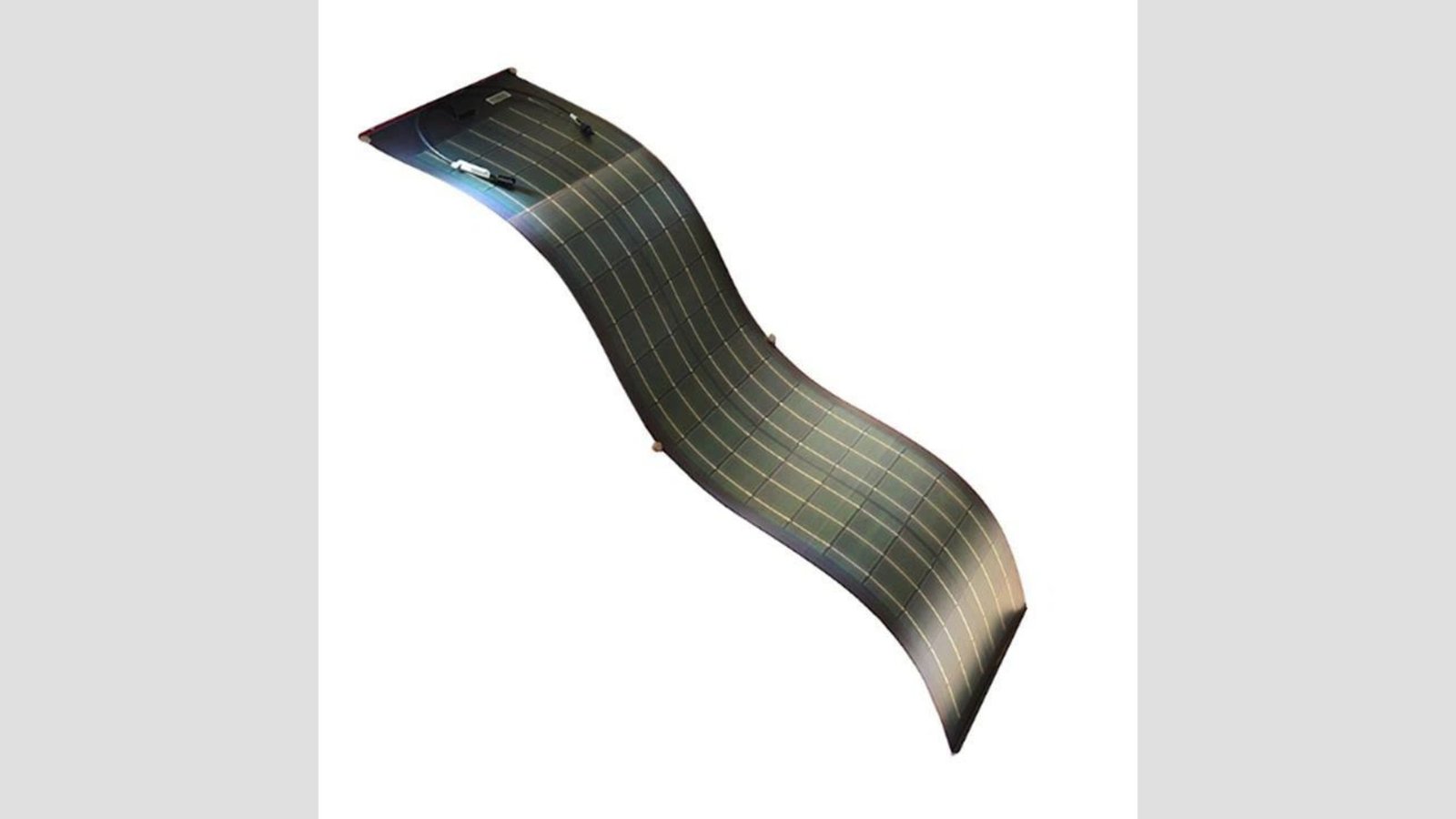

CIGS panels outdoors have a 360° flexibility compared to other solar technologies due to their higher durability and efficiency, lower temperature coefficient, and compact and lightweight materials.

There is a huge potential for CIGS technology to integrate into several applications such as BIPV, Portable electronics and vehicle integration which will be discussed later in detail…

Lower Production Costs

Compared to other solar technologies, the manufacturing process of CIGS solar cells results in lower production costs due to its thin film technology that reduces the use of semiconductor materials. As the costs decrease per unit with the increase in production volume.

The non-vacuum deposition process is cheaper than the vacuum one due to the involvement of specialized processes such as sputtering that consume less energy.

For instance, a solar cell with a production capacity of 1000 MW per year and 15% efficiency, will have a production cost of $0.34 per watt approximately.

Disadvantages of CIGS solar cells

On the other side, you need to know the disadvantages of CIGS solar cells that make people think if it is worth the investment or not:

- Material Scarcity

- Manufacturing Complexity

- Environmental and Health Concerns

Material Scarcity

The core elements of CIGS solar cells such as Indium and Gallium aren’t the most abundant ones on earth and due to the insufficient capacity of mining, it leads to scarcity of materials. 90% of Indium is the by-product of Zinc. Similarly, the Gallium is sourced during the production of Alumina (95%) and Bauxite (5%). It becomes evident that the supply is uncertain which is dependent on the availability of other metals. The huge demand has resulted in high rates of Indium ($562.70 per kg) and Gallium ($755.80 per kg).

It is predicted that the shortage of Indium and Gallium could limit the scalability in future. In other terms, the production volume decreases with the increase in the cost to an unimaginable extent.

Manufacturing Complexity

The complexity of the deposition process of CIGS can slow down the manufacturing for several factors:

- Difficulty in controlling multiple elements like Copper, Indium, Gallium, and Selenium.

- Accuracy in controlling the deposition and temperature rates during the multi-stage process: Indium-Gallium and Copper-Selenium.

- The deposition process might require the usage of toxic gases like Se or H2Se, and annealing temperatures that affect the quality of CIGS thin films.

Environmental and Health Concerns

There are higher chances of an increase in environmental and health concerns, such as:

- Heavy metals used in CIGS cells have high atomic weight and possess a larger degree of toxicity. These metals are non-biodegradable and can contaminate the quality of drinking water resources. As a result, the survival of all living creatures is threatened due to the reduction in crop productivity.

- Various health concerns such as cancer in human beings can happen due to genetic mutations. It occurs when plants absorb these heavy metals and get affected, which results in a reduction in biodiversity.

CIGS vs Other Solar Cells: An Important Comparison to be known!

Here is the detailed comparison of CIGS and other solar cells tabulated below based on several factors:

| S.No | Factors | CIGS Solar Cells | CdTe Solar Cells | Amorphous Solar Cells | Crystalline Solar Cells |

| 1. | Efficiency | 12% to 14% | 22% | 6% to 7% | Monocrystalline: 15% to 24%

Polycrystalline: 13% to 16% |

| 2. | Cost | $2.8 to $2.9 per watt | $0.46/Watt | $0.50 to $1.50/Watt | $0.70 to $1.50/Watt |

| 3. | Temperature Coefficient | -0.36 % / °C | -0.21 % / ℃ | −0.26 % / ℃

to -0.45 % / ℃ |

Monocrystalline:

-0.3 % / ℃ to -0.5 % / ℃ Polycrystalline: -0.3 % / ℃ to -1 % / ℃ |

| 4. | Durability | Same as Crystalline panels | Higher | Less | Strong and long-lasting |

| 5. | Environmental Impact | Higher | Lower | Higher | Higher |

Applications of CIGS solar cells

The CIGS solar cells can be categorized based on the present and future applications:

1. Present Applications:

- Building-integrated photovoltaics (BIPV) such as windows, roofing materials and exterior walls have advanced cutting-edge technology to generate electricity as well as enhance the aesthetics of the buildings.

- Portable electronics like laptops, smartphones, and chargers are ideal for the integration of the CIGS solar panels.

- Aerospace devices like Satellites, Spacecraft, Space stations and several others.

- Vehicle integration such as electric cars, buses, trains, and drones and many more…

2. Future Applications:

- Ultrathin Solar Cells with a thickness 10 times less than the standard solar cells can efficiently convert solar into electrical energy that saves material usage, and deposition time and improves carrier collection in faulty absorber materials.

- Development of Lightweight and Flexible photovoltaic solar cells that can be installed and operated in weight-restricted places, curved surfaces or inability to utilize standard silicon solar cells. Also, it is expected that the efficiency will be enhanced by greater than 20%.

Ray is an avid reader and writer with over 25 years of experience serving various domestic and multinational private and public energy companies in the USA.