In the early 7th century B.C., humans used solar energy concept to light fires with magnifying glass materials. However, 1839 witnessed a major development in solar panel technology with Edmond Becquerel’s discovery of the photovoltaic effect. Later, the solar panels in the 1970s evolved into monocrystalline and polycrystalline made using pure silicon. Currently, the best solar panels have a 22% efficiency and are available for commercial use.

There are different types of solar cells available in the market namely crystalline silicon-based (Monocrystalline and Polycrystalline), PERC and Thin film.

It would be exciting to know what the future of TOPCon solar cells is by knowing its advantages and disadvantages. Mainly, you need to understand how TOPCon is made which varies from PERC and Heterojunction solar cells based on the manufacturing cost, temperature processing, degradation and bifaciality rate.

What are TOPCon Solar Cells?

TOPCon is a unique type of solar panel technology that aims to improve efficiency. It uses a thin layer of insulating material known as the tunnelling oxide layer between the metal contact and the solar cell to create a tunnelling junction that allows better electron transportation and collection for higher cell efficiencies.

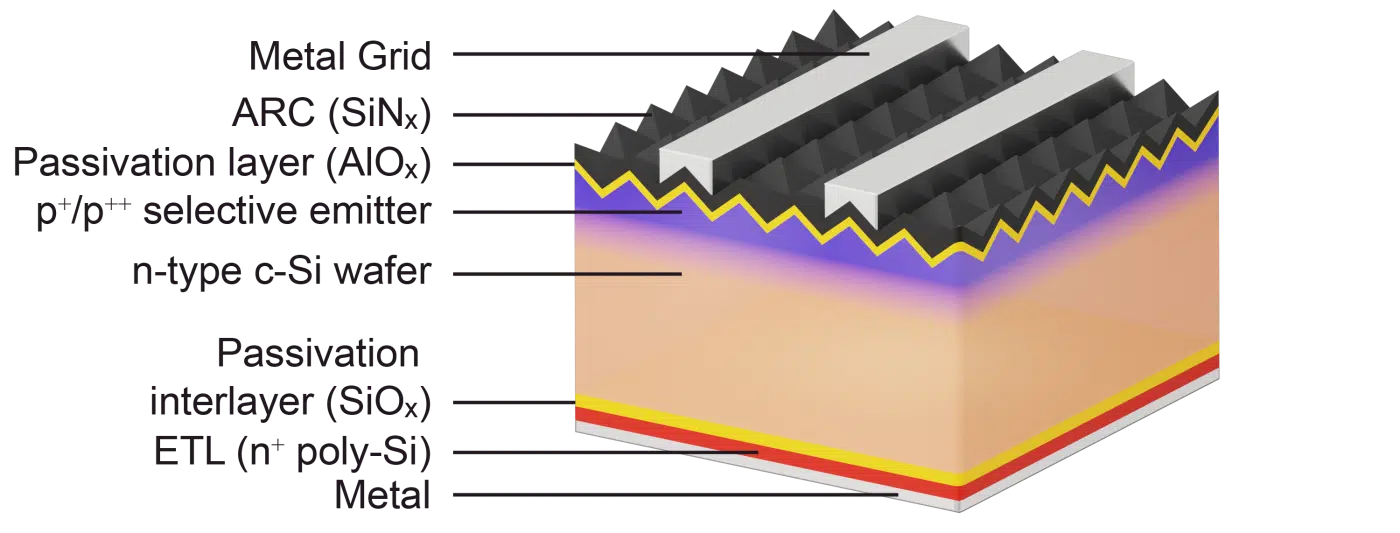

Both the TOPCon and PERC solar cells appear the same visually after installation and have a good light absorption capability. However, TOPCon is composed of N-doped silicon, a complex material during the manufacturing process, whereas the PERC uses P-doped silicon. In other words, the improvement of PERC yields in the manufacturing of TOPCon solar cells.

Between the n-type silicon surface and a highly doped polysilicon layer, you can find an ultra-thin tunnelling oxide layer which forms the core part of the TOPCon solar cell’s structure to protect from moisture and temperature fluctuations, thereby avoiding breakdowns. Also, the TOPCon solar panels are designed in such a way to perform well in low light and shaded conditions.

By considering the base structure of the PERC solar cell, an ultra-thin silicon dioxide layer that works as the tunnel oxide layer and the phosphorous-doped polycrystalline silicon (n+ Poly-Si) layer replace the back surface field layer. These modifications improve the existing surface of PERC solar cells by enhancing the overall cell efficiency which is achieved by improving light absorption and reducing electron recombination rates.

How are TOPCon Solar Cells Made?

The TOPCon solar cells are made similar to the PERC cells by making a small investment to upgrade the existing production line. Here are the following additional steps that explain how TOPCon solar cells are manufactured:

1. A wafer structure is chemically textured using a potassium hydroxide (KOH) to separate the saw damages from the cutting processes from the c-Si wafer.

2. Boron Tribromide is removed from the backside using wet chemistry. Additionally, by applying, Nitric Acid and Hydrofluoric Acid (HF/HNO3) solutions the impurities are eliminated. Consequently, through the wet chemical dipping, the ultra-thin oxide layer is produced.

3. The n+ Poly-Si layer is formed by growing the amorphous silicon (n-a-Si: H) layer which is phosphorous-doped through the process of plasma-enhanced chemical vapour deposition (PECVD) and later annealed at 900ºC.

4. Using the oxidation-reduction method, a high-quality n-a-Si layer of thickness 100 to 200 nm is grown on the P-type material.

5. To create a metallic aluminium (Al) or Silver (Ag) coating on the n-a-Si layer, an electrochemical deposition process is used that serves as a metal contact surface for the front side of the TOPCon cells.

6. The rear side of the TOPCon cells is applied with water oxide (H2O) or hydroxide (OH) to form a transparent conductive film.

7. Through the PECVD process, the passivation process enhances the lifecycle of the solar cell and reduces surface recombination.

8. The separation of TOPCon cells from the surrounding material is possible through detection and sorting.

9. Finally, the TOPCon cells are manufactured when the Silver (Ag)/ Aluminium (Al ) junctions are applied through screen printing for the metallization process starting with a minimum temperature of 760ºC. Typically, it requires a temperature of 900ºC to 1000ºC.

Advantages of TOPCon Solar Cells

Here are the several advantages of TOPCon Solar Cells such as:

- Higher Efficiency

- Lower Temperature Coefficient:

- Higher Bifaciality rate

Higher Efficiency:

Due to the higher resistance to impurities, TOPCon has an efficiency of up to 26.1% which is more than PERC ( 24.5%). Though HJT Solar cells excel in efficiency (26.56%) approximately, the manufacturing complexity is extremely high.

Lower Temperature Coefficient:

A lower temperature coefficient is needed for solar panels to increase their efficiency with minimal losses. The temperature coefficient is typically expressed in %/°C. In simpler terms, it is the rate of output increased or decreased per 1 °C starting from the standard temperature of 25 °C. Commonly, you can find a majority of solar panels with a temperature coefficient between -0.2% /°C to -0.5%/°C.

Higher Bifaciality rate:

The Bifaciality rate is the ratio of power output from the rear side of the solar panel to the front side. It means that the higher Bifaciality rate of solar panels can generate huge power on both sides, which is beneficial in areas where there is a huge amount of reflected light. This type of solar cell basically used in bifacial solar panel.

TOPCon solar cells have a Bifaciality rate of 80 to 85% approximately which is higher than the PERC modules (70%).

Disadvantages of TOPCon Solar Cells

Despite its numerous benefits, there are certain disadvantages of TOPCon solar cells you need to know:

- Higher degradation rate

- High manufacturing Cost

- High-temperature processing

Higher degradation rate:

A higher degradation rate occurs due to Light-Induced Degradation (LID) and Light and Elevated-Temperature Induced Degradation (LeTID). Also, the negatively doped n-type TOPCon cells are more prone to moisture than the positively doped P-type cells. Additionally, the TOPCon cells are sensitive to Ultraviolet-Induced Degradation (UVID) which can affect the longevity of the cell.

High manufacturing Cost:

The TOPCon solar cells have higher manufacturing costs when silver (a precious metal) is used at the top and bottom layer to close the circuit, which not only influences the overall cost but also increases the complexity. Additionally, the complex manufacturing process as discussed above increases the production cost.

High-temperature processing:

The fabrication of TopCon solar cells requires a higher temperature process of around 900ºC to 1000ºC during the annealing process. If these processes are powered by fossil fuels, it can lead to a carbon footprint that contributes two-thirds of the solar energy lifecycle emissions.

TOPCon vs PERC vs Heterojunction Solar Cells

Here is the interesting comparison of TOPCon vs PERC vs Heterojunction solar cells based on the following factors:

| Factors | TOPCon Solar Cells | PERC Solar Cells | Heterojunction Solar Cells |

| Cost | Expensive, but cost-effective

($0.160 to $0.281 per watt approximately) |

Moderate Cost

($0.046 per watt) |

High Costs

($0.48 to $0.56 per watt) |

| Efficiency | 26.1% | 24.5% | 26.56% |

| Materials Used | N-type silicon and thin tunnelling oxide | Passivated emitter rear cell | Polycrystalline silicon layer |

| Manufacturing Complexity | Complex | Less Complex | Simple |

| Bifaciality rate | 80 to 85% | 70% | More than 90% |

| Durability | More advanced | Higher | Greater |

What is the Future of TOPCon Solar Cells?

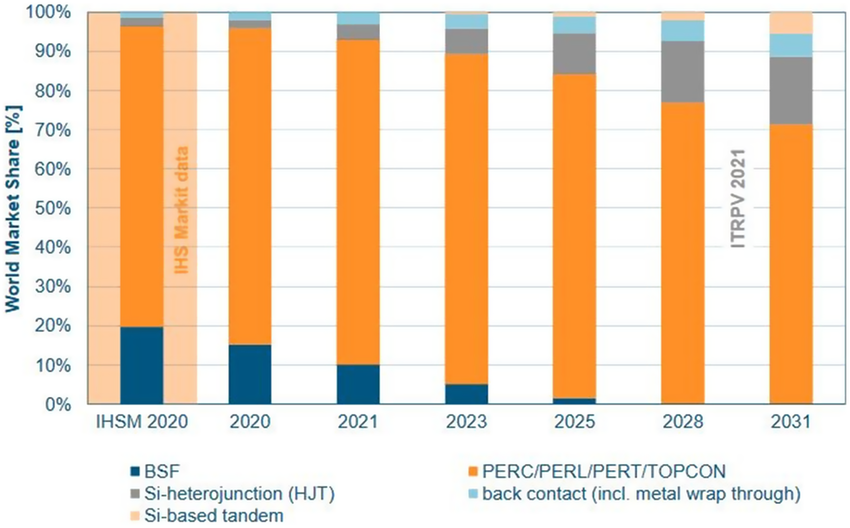

Image Source: ResearchGate.net

TOPCon Solar cells are gaining higher popularity in recent times having a higher efficiency of 26.1% and the upgraded version of PERC solar cells will have a high growth in future.

The latest reports of the National Renewable Energy Laboratory (NREL) state that the TOPCon solar cells have achieved up to 28% conversion efficiency, thereby highlighting the latest developments in technology.

The TOPCon cells accounted for about 10% of the global solar cell market in 2022 and possibly the market share can reach up to 60% in 2033 based on the survey of the International Technology Roadmap for Photovoltaic (ITRPV). Also, the global TOPCon solar cells market size was approximately USD 6.5 billion in 2022, and it is anticipated to increase upto USD 28.3 billion by 2030, with the improvement of a compound annual growth rate (CAGR) of 23.35%.

Ray is an avid reader and writer with over 25 years of experience serving various domestic and multinational private and public energy companies in the USA.