Solar cells are photovoltaic cells fabricated from silicon that convert sunlight into electricity through the photovoltaic effect to generate electricity.

Alexandre Becquerel established modern solar cell technology by observing the photoelectric effect in certain materials. However, Charles Fritt in 1883 designed the first solar cell by coating selenium with a thin layer of gold. In 1954, Bell Laboratories produced the first solar photovoltaic cell gaining an efficiency of up to 4%. Finally, the solar technologies gained huge popularity by the 1970s.

The PERC solar cells stand for “Passivated Emitter and Rear Cell”. Also, known as the “Passivated Emitter and Rear Contact”, it indicates the efficiency of a solar cell. The solar panels made up of PERC cells have a higher conversion rate of sunlight into electricity.

In 1983, the University of New South Wales described the term PERC technology and officially registered it in a paper in 1989. The PERC modules have an efficiency of more than 20% through the PERC cells that have been the benchmark for several years in the solar industry by proving their worth.

If you’re eager to learn more about solar panels, you should know the comparison of PERC Solar Cells vs Traditional Solar Cells by knowing how each type works, and its advantages and disadvantages. This will help you to decide if Perovskite or Heterojunction solar cells can also be a perfect alternative to PERC or not. Mainly, you will find it interesting to know the emergence of Tunnel Oxide Passivated Contact and its promising solutions to overcome standard cells.

PERC Solar Cells vs Traditional Solar Cells

Here is a brief comparison of PERC and traditional solar cells in terms of their structure and function:

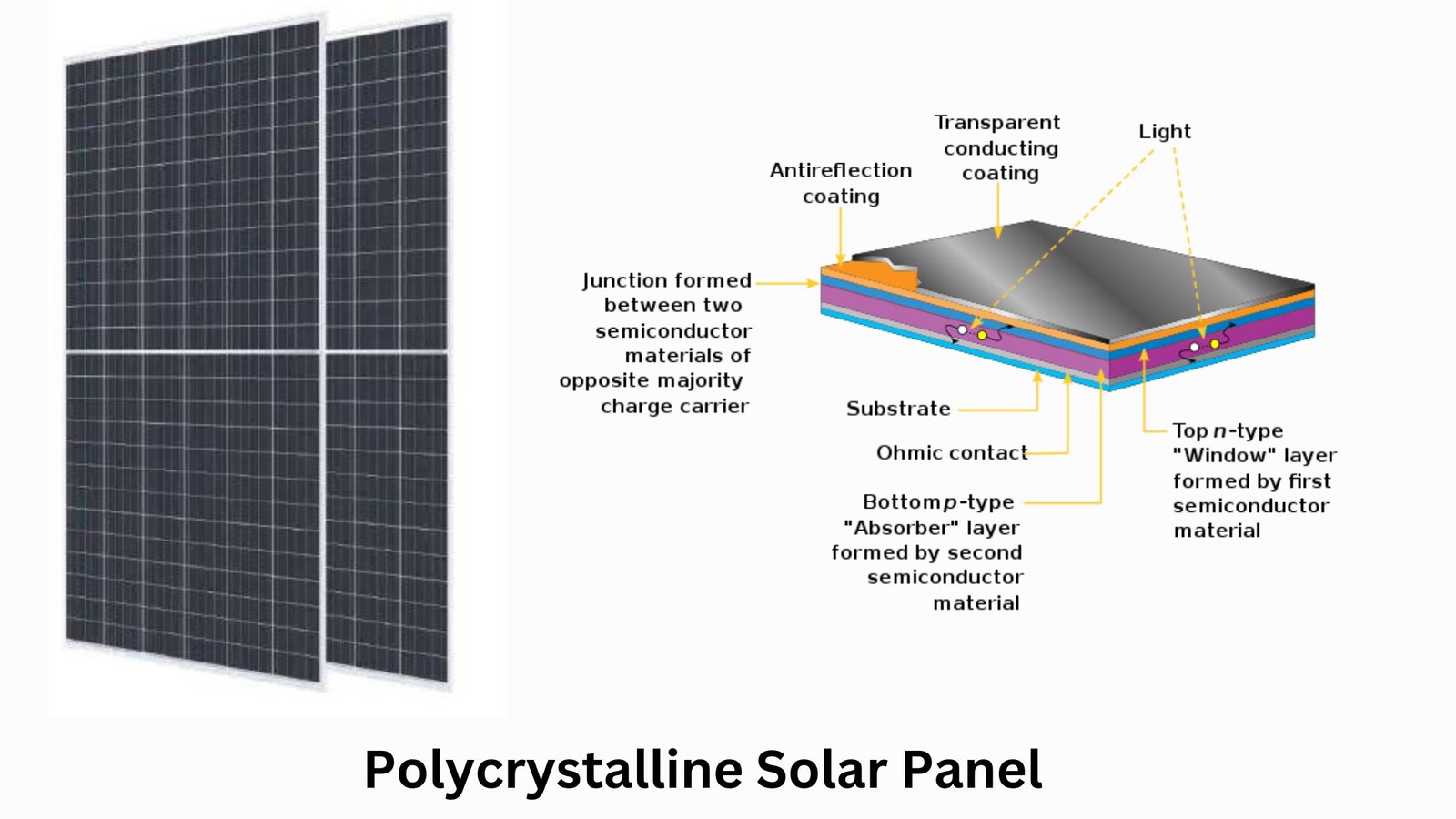

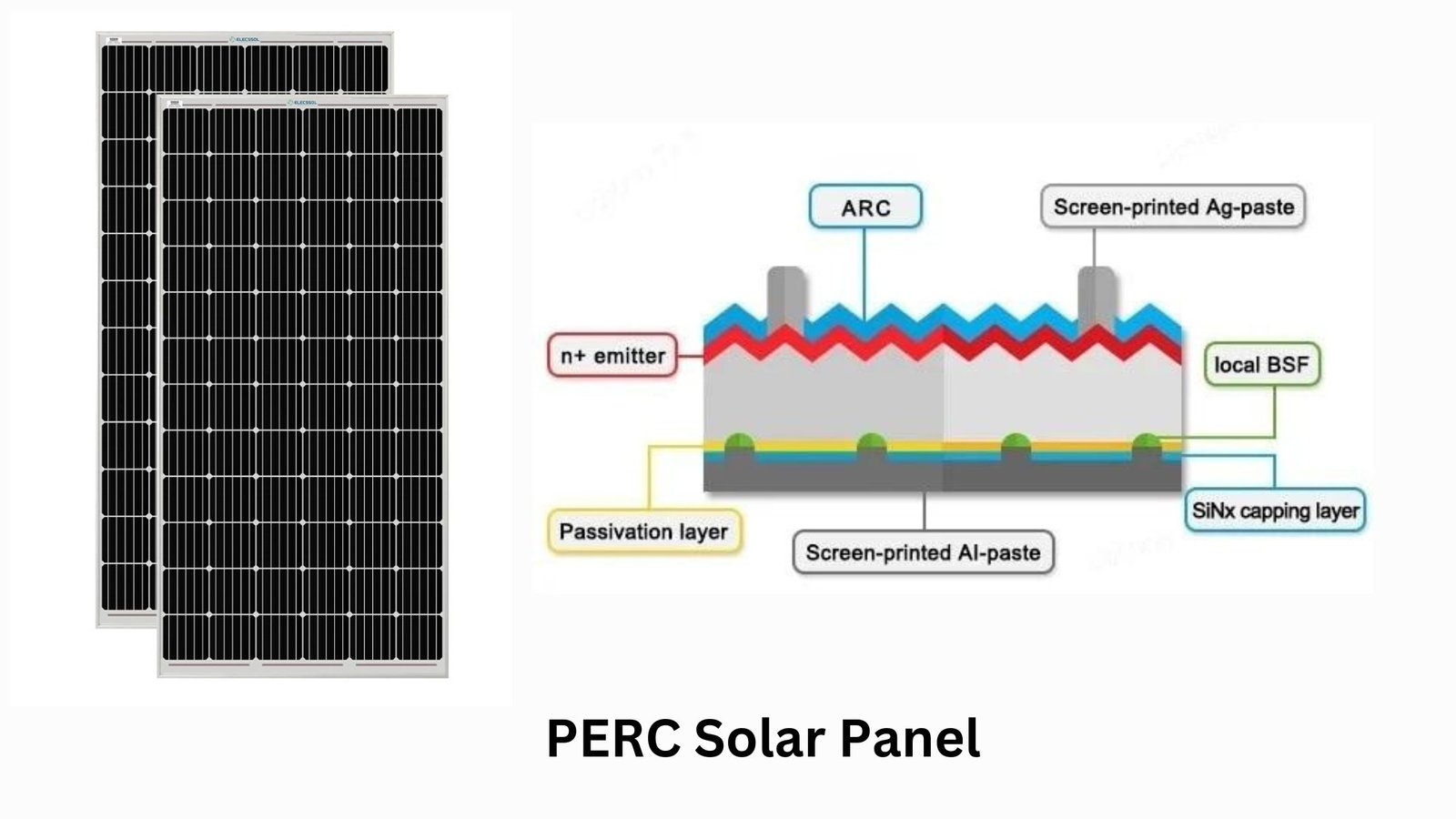

1. Structure: PERC solar cells have an extra layer on their back. Whereas, the traditional solar cell has an anti-reflective coating on one side to minimize reflection.

2. Functioning: PERC solar cells have higher efficiency due to the rear layer which reflects some sunlight into the cell by giving it another chance to absorb the light and convert it into electricity. It can produce energy from the bifacial solar panels. Conversely, traditional solar cells generate electric current when sunlight strikes the P-N junction to excite electrons and create electron-hole pairs.

How Do Traditional Solar Cells Work?

Traditional PV solar cells are made from crystalline silicon that produces electricity without relying on chemical reactions or fuel. It is used in several applications like installations on residential and commercial rooftops, off-grid power systems, solar farms and space projects (Solar panels powered satellites, space probes and International Space Stations). There are basically two types of traditional solar cells: monocrystalline and polycrystalline.

Typically, its structure includes an Absorber Layer, P-N Junction, Electrodes and Contacts, and a protective coating (safeguards from mechanical shocks and several environmental factors such as moisture, oxygen, etc).

The sunlight reaches the p-n junction through an anti-reflective coating that reduces reflection and enhances light-absorbing capacity. Electron hole pairs are created within the junction through the absorbed light energy. In the depletion layer near the p-n junction, the electrons move to the n-type side and holes to the p-type side.

An electric field is created to produce a photovoltaic effect, which is caused due to the difference between the p and n regions that prevents electrons from flowing freely back to the junction. These cells combined into solar panels can generate substantial amounts of renewable energy to power various electrical appliances.

How Do PERC Solar Cells Work?

- Anti-reflective coating (ARC) – to minimize reflection and enhance light absorption

- Screen-printed Silver paste – to form the front contact of a cell

- Silicon wafers to create the P-N Junction – The core component of the solar cell known as a doped semiconductor

- Local Aluminium Back Surface Field (BSF) – to improve charge accumulation

- Dielectric passivation layer – improves stability

- Screen-printed Aluminium paste layer – provides corrosion and contact resistance.

The combining of electron-hole pairs at the cell’s surface rather than contributing to the electric current is known as Surface Recombination. The solar cells’ reduced efficiency is due to the lower power output. Unpaired dangling bonds in the unprocessed surfaces trap charge carriers, leading to recombination. The surface defects or impurities act as recombination centres.

PERC collar cells can reduce surface recombination through Dielectric Surface Passivation (covering the rear surface to minimize the chances of electrons recombining with holes), diminishing the area of contact for semiconductor materials that mitigate charge carrier recombination and increase efficiency. Also, the enhancement of rear surface reflection allows more photons to get absorbed easily.

Laser doping introduces dopants like Phosphorus and Boron in exact regions of solar wafers used in cells. The lasers for diffusing the dopants create contact regions within the solar cells. It helps to reduce the surface recombination to improve overall cell efficiency.

The mono PERC are single silicon crystals which is the advanced version of monocrystalline cells that have high efficiency even during the low light conditions. Whereas, poly PERC is made by melting different silicon fragments together and is a cheaper option as it has lower efficiency than mono PERC.

Advantages of PERC Solar Cells

There are several advantages of PERC solar cells:

1. Solar panels built with PERC cells have higher energy conversion efficiency than the standard ones, thereby converting sunlight into electricity more easily.

2. The additional layer to the backside of the solar cells helps to perform better in low-light and high-temperature conditions.

3. Manufacturers can start producing high-efficiency PERC cells at lower costs.

4. It has a higher lifespan (21 to 24%) than the conventional ones, which leads to greater return on investment (ROI) for both residential and commercial installers.

5. The higher flexibility provides many attractive opportunities for various applications like bifacial solar panels and solar trackers.

Disadvantages of PERC Solar Cells

On the other side, you need to consider the disadvantages of PERC solar cells:

1. Light-induced degradation (LID) is a phenomenon that occurs when solar cells’ efficiency degrades after a certain time due to direct sunlight exposure, which causes a performance loss of 0.25 to 0.7% per year. The LID is caused due to the presence of Boron as the dopant in the crystalline structure of silicon. Also, it causes a temporary reduction in efficiency.

The three different testing techniques in research namely LID techniques, LID stabilization test and electrical carrier injection are done during the early stages of manufacturing solar cells to ensure quality assurance and reliability to ensure the low levels of LIDs.

2. Potential-induced degradation (PID) occurs when silicon solar cells are converted into modules due to the high voltage applied between the frame and cells during the operational process. As a result, the efficiency and power output are reduced There is a 14% degradation of power resulting in enhanced carrier combination at the back side of the cell. Mainly, the PID is caused due to the diffusion of Sodium (Na+) ions from the front glass and the excess leakage of current along the transmission route.

However, several researches have resulted in mitigating these issues by developing materials such as conductive polymers, anti-reflective, and specialized coatings. Also, preventative strategies such as bypass diodes and DC-DC converters help to overcome the drawbacks.

Alternative to PERC Solar Cells

The PERC solar cells face severe competition from various alternative technologies such as

- Perovskite Solar Cells

- Heterojunction Solar Cells

- Tunnel Oxide Passivated Contact (TOPCon) solar Cells

Perovskite Solar Cells

Perovskite Solar Cells are thin-filmed cells that contain a perovskite-structured compound as the light-absorbing layer to convert into electricity.

Unlike the PERC cells made of crystalline silicon, Perovskite is made from the following combination of materials in the form of “ABX3”. Here “A” is an organic cation like methyl ammonium (CH3NH3+, MA+) or formamidinium (CH(NH2)2+, FA+), and “B” is an inorganic cation like Lead (Pb) and Tin ( Sn). Also, “X” is a halogen anion such as Chlorine (Cl−), Bromine (Br−) and Iodine ( I−).

ADVANTAGES:

- Higher improvement in conversion efficiency from 3% in 2009 to more than 25% in 2021

- Low cost of raw materials and fabrication methods

- Ultra-thin sheets of 500 nm can help to absorb the visible sun spectrum

DISADVANTAGES:

- Due to external factors like heat, light, oxygen and water, the Perovskite solar panels are highly unstable

- The business model is yet to become popular

Compared to the PERC, Perovskite Solar Cells have better light absorption capabilities than crystalline silicon. Also, they have improved tolerance to handle defects and function well despite the impurities and imperfections.

In 2022, the global perovskite solar cell market size was $94.8 million, and possibly it can cross more than $2480 million at the end of 2032 with a CAGR of 39% from 2023 to 2032.

Heterojunction (HJT) Solar Cells

The silicon Heterojunction (SHJ) or Heterojunction with Intrinsic Thin Layer (HIT) solar cells are a type of photovoltaic solar cell technology formed between semiconductors with varying band gaps. In other words, the HJT is a combination of crystalline and thin film solar cells.

The Heterojunction solar cells require less manufacturing process under low-temperature conditions than the PERC cells.

ADVANTAGES:

- Higher laboratory efficiency of 27%.

- Reduced recombination process

- Improved performance in hot climates

- Bifacial factor (Captures light from both surfaces) with an energy output of more than 90%

DISADVANTAGES:

- Complex manufacturing process with fewer steps

- Highly sensitive to humidity and moisture

- Thin layers of solar cells are sensitive to temperature

- Requires Higher budget

- Limited scale technology

Overall, the HJT solar cells are highly efficient and have a lower degradation rate than the PERC. This is because the life cycle power generation is 1.9 to 2.9% higher than PERC cells.

The HJT solar cell market had a value of around $1.50 billion in 2022 and is expected to grow by $6.67 billion by 2030. However, the production cost of HJT solar cells is $0.14 per watt which is higher than PERC cells of $0.11 per watt.

Tunnel Oxide Passivated Contact

Tunnel Oxide Passivated Contact or “TOPCon solar cells” consist of a core element “Tunnel Oxide” which develops a passivated contact to minimize the recombination of charge carriers at the interface. It develops a delicate layer of oxide between polysilicon and base crystalline silicon. These cells are composed of n-doped silicon to attain higher efficiency levels.

While PERC adds a passivated layer to the rear layer of solar cells for increased light absorption, the TOPCon uses the same PERC film to include an additional ultra-thin layer of oxide to possess the unabsorbed light. Also, it can resist higher voltages to increase overall efficiency.

ADVANTAGES:

- Easy to work with

- Higher levels of Efficiency

- Abundance of raw materials

- Budget-friendly manufacturing process

- Less sensitive to temperature

DISADVANTAGES:

- Huge production cost

- Requires High Temperature for processing

- Highly sensitive to impurities

- Complex manufacturing process

TOPCon is an upgraded version of PERC solar cells with improved efficiency, power output and manufacturing process. It can be used in various applications like portable solar chargers, off-grid cabins, and small boats.

Currently, the TOPCon solar cells are available in the market which are nearing the price of PERC cells. In 2022, the market size was $8.96 Billion at a CAGR of 23% and has a higher possibility to surpass more than $69.58 Billion approximately by the completion of 2032.

Are PERC Solar Cells worth it?

Yes, Homeowners and business owners can prefer PERC solar cells as it is completely worth the money spent. The higher efficiency and overall energy production resulted in the PERC panels showing tremendous performance in higher temperature environments, inferior sunlight or cloudy conditions.

Typically, it performs better than conventional solar cells with the boosted efficiency through the additional layer at its backside and improves cell production.

While there are several benefits, the cost of PERC cells is slightly more expensive than PV solar cells due to the increased production and huge availability of Mono PERC technology that is easily accessible to a more expansive market.

The average cost of PERC panels ranges between $2.00 to $3.00 per watt, which is higher than that of the standard panels $1 to $1.50 per watt approximately. However, these prices tend to fluctuate regularly, and you must check with a particular manufacturer or retailer.

Ray is an avid reader and writer with over 25 years of experience serving various domestic and multinational private and public energy companies in the USA.