A photovoltaic cell, also known as a solar cell, converts sunlight into electricity using nanotechnology. The term “photo” means “light” and “voltaic” refers to “electricity”.

In 1839, Alexandre Edmond Becquerel- a French scientist, discovered the photovoltaic effect. However, the first solar cell was developed by the American inventor Charles Fritts in 1883 using selenium and achieved an efficiency of around 1%.

Typically, solar cells are made of Silicon, which is the commonly used semiconductor material due to its high availability and low cost.

The science behind solar cells evolves producing a photovoltaic effect that absorbs the photons of sunlight when it strikes the panels through a thin layer of semiconductor material (silicon) to release electrons. As a result, clean and renewable energy is generated during the direct conversion of sunlight into electricity process without emitting any greenhouse gases or other pollutants. The electricity generated can be used to power devices or fed into the grid. You can learn in detail about how solar panels work.

The new developments in PV technology can be found in different applications such as residential, commercial and industrial solar systems, portable solar chargers, vehicles and transportation, utility-scale solar farms, water pumping and irrigation, and several others.

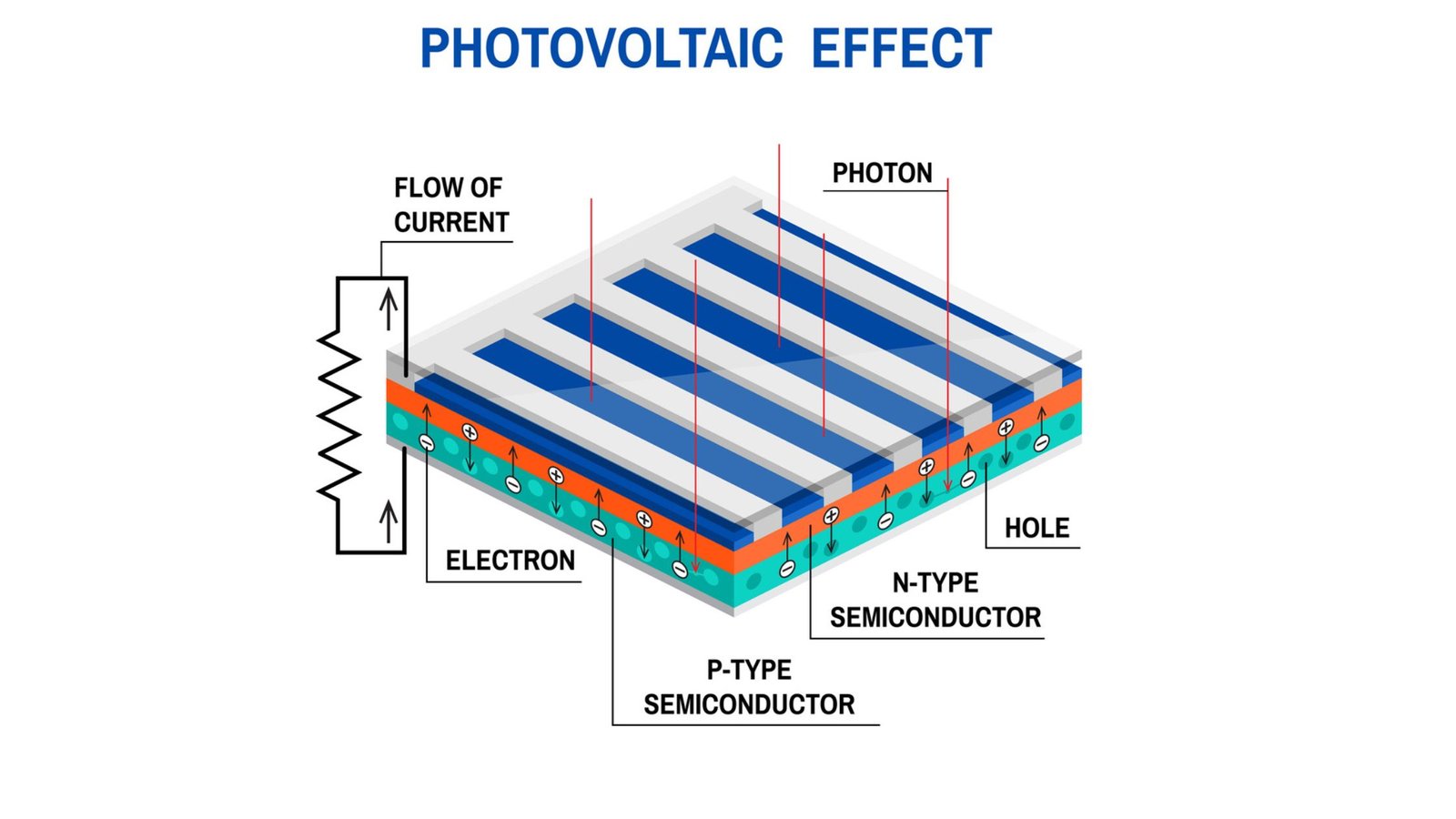

The Science Behind Solar Cells: The Photovoltaic Effect

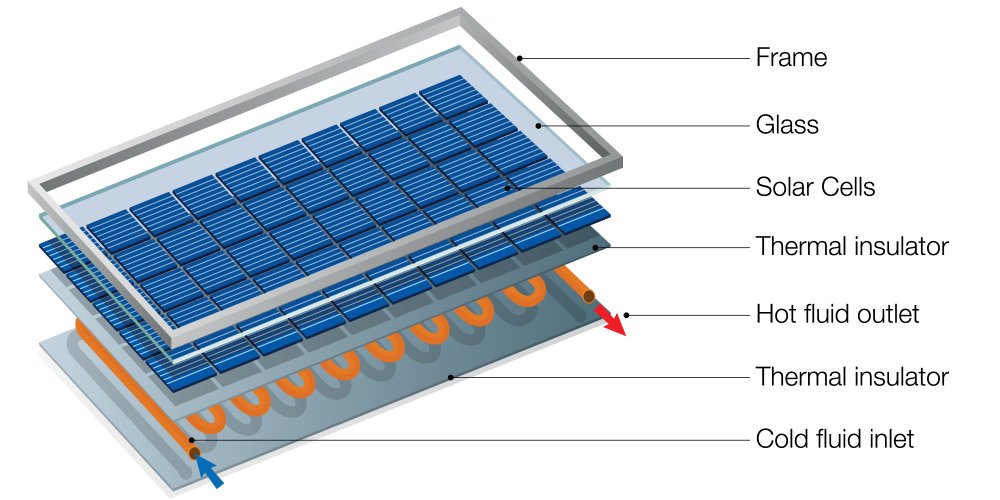

1. Sunlight Absorption: The solar cells are made up of layers of crystalline silicon with a hard protective layer of non-reflective glass which absorbs the photons from the sunlight.

2. Electrons Hole Pair Generation: The photons transfer the electrons through a semiconductor material which generates electron-hole pairs after exciting from the ground state to break the atomic bonds.

3. Separation of the electric field: The solar cell is designed with an electric field that creates a p-n junction with one layer positively charged and another negatively charged, thereby separating an electric field. The separation occurs within the semiconductor material when the excited electrons and positively charged holes are left behind. Through the internal structure of the solar cell, an electric field is created.

4. Generating electricity: The excited electrons (towards the negative side) and holes (towards the positive side) move in the opposite direction to generate electricity.

5. Collecting Current: The electric current generated by the movement of electrons and holes can be collected through the metallic contacts attached to the top and bottom of solar cells.

6. Current Conversion: Every solar cell produces direct current (DC) which is converted into alternating current (AC) using an inverter to power electrical appliances and devices.

Photovoltaic cells are primarily made of silicon which are found in various types such as Monocrystalline, Polycrystalline, Thin-film, Perovskite and Amorphous. Additionally, different types of semiconductor metals like Copper indium gallium diselenide (CIGS), and cadmium telluride (CdTe) are used in solar cells.

Overall, the photovoltaic effect is a process of converting sunlight into electricity using solar cells causing the release of electrons.

What are Solar Cells Made Of?

These are the four main steps that make the conversion process of raw materials into solar cells namely:

1. Silicon Purification: It is the first step in solar cell manufacturing to purify silicon which is extracted from silica sand using Siemens process. Silicon dioxide (SiO2), which naturally occurs in the form of quartz, is separated into Silicon (Si) and the Oxygen (O2) is removed by undergoing a reaction with Carbon (C). Furthermore, the quality of the silicon is enhanced by removing impurities like iron, aluminium and other metals.

2. Wafer Production: Once the silicon is purified, it is melted and formed into cylindrical blocks or ingots through the Czochralski process. Using the diamond wire saws, these ingots are sliced into thin wafers. To improve light absorption and reduce surface reflection, the silicon wafers undergo surface treatment processes like polishing and texturing.

3. Cell Design: The solar wafers are processed to create basic designs of solar cells which include steps like doping, formation of PN Junction, passivation, and metallization.

4. Assembly into panels: Solar panels are assembled after the individual fabrication of solar cells. By connecting multiple solar cells in series or parallel you can achieve the desired voltage and current output.

Mainly, doping is the process of altering electrical properties by introducing semiconductor materials like silicon. It is a crucial step in the manufacturing process of solar cells to create the required characteristics for the photovoltaic effect.

A P-type silicon is a doped silicon of a group III element in the periodic table such as Boron. The positively charged carriers are introduced into the silicon structure also known as “holes”.

Whereas, an N-type silicon is doped from the group V element of the periodic table such as Phosphorous that produces negatively charged carriers into the silicon crystal structure.

You can also read about how solar panels are made to get a better idea of photovoltaic cells (solar cells).

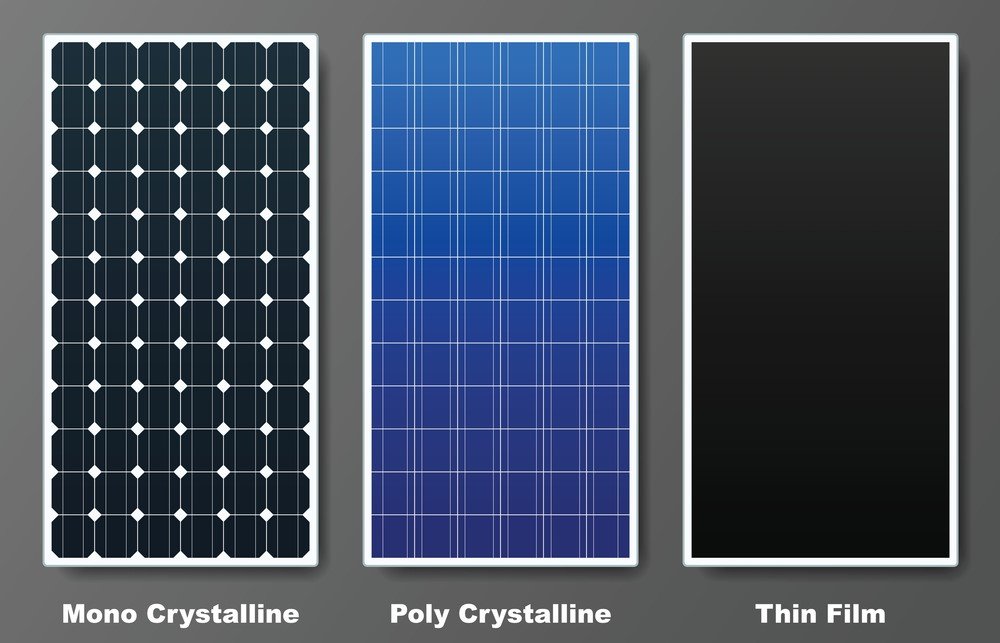

Types of Photovoltaic Cells

Four main types of PV cells are currently available in the market and widely used which are better than the standard cells such as:

1. Monocrystalline Silicon:

- Material: Single silicon crystal

- Cost: The complex manufacturing process results in higher costs

- Efficiency: 15 to 24%

- Output: Higher output due to efficient sunlight absorption capacity

2. Polycrystalline Silicon:

- Material: Silicon wafers

- Cost: Lower than monocrystalline cells due to production-efficient techniques

- Efficiency: 14 to 16%

- Output: Lower than monocrystalline silicon due to less sunlight absorption capacity.

3. Thin-Film Silicon:

- Material: Thin layers of semiconductor materials deposited on glass, plastic or metal surfaces.

- Cost: Less expensive than mono-silicon and poly-silicon cells.

- Efficiency: 18.7 to 21.7%

- Output: Lower than monocrystalline silicon due to less sunlight absorption capacity.

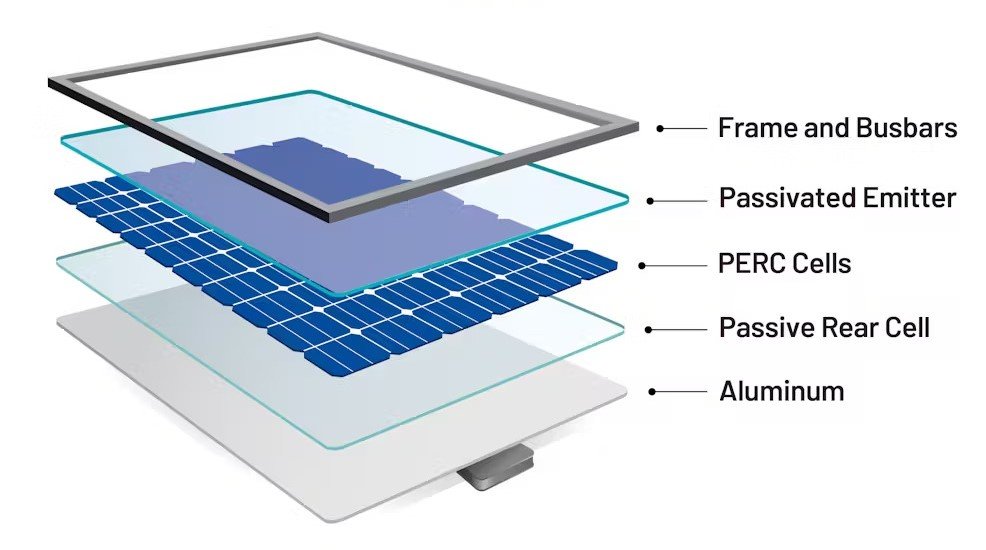

4. Passivated Emitter and Rear Cell (PERC):

- Material: Advanced silicon cells with protective layers.

- Cost: Higher than mono-silicon cells due to the extra process for improving sunlight absorption.

- Efficiency: 23%

- Output: Higher than mono-silicon due to improved absorption.

Out of these four types, Monocrystalline Silicon is widely used due to its higher efficiency.

New Developments in Photovoltaic Cell (PV Cell) Technology

The Photovoltaic cell technology is rapidly improving with innovative developments by introducing five main types of solar cells that are not yet available in the market due to the ongoing research process such as:

1. Perovskite Solar Cells have high efficiency, easy manufacturing process and low-cost materials. Researchers have developed innovative techniques in fabrication which improve the stability and scalability. Compared to standard solar cells, Perovskite has a higher efficiency of 25%.

2. Organic Solar Cells use organic materials with a thickness of 100 nm range to convert sunlight into electricity. The advancement in material design, device structure and manufacturing process increases the stability. It holds an efficiency of 19%

3. Quantum Dot Solar Cells use tiny semiconductor particles called quantum dots that capture sunlight and convert it into electricity and exceed the efficiency above 20%.

4. Multijunction Solar Cells include multiple layers of different semiconductor materials that capture different ranges of solar radiation and increase efficiency by more than 40%. There is a lot more to know about multijunction solar cells.

5. Transparent Solar Cells can harness the sun’s radiation by integrating the technology into windows and building outer walls and achieving a power conversion efficiency above 10% and transparency over 50%.

In recent times, AI has played a major role in optimizing the design and manufacturing process of solar panels to improve efficiency and reduce costs. AI-powered systems can improve the overall quality of solar panels by identifying the defects in solar cells.

Also, the consumption of non-renewable sources is lowered by reducing carbon emissions. You can monitor complex processes by gaining real-time insights if you’re a house owner, grid operator or have solar farms. The user-friendly interface helps to identify intense issues before they become major problems, thereby extending the lifespan of solar panels and equipment connected.

Conclusion

In the present world, Photovoltaic cells play a crucial role by converting towards sustainable energy sources by harnessing sunlight to generate electricity. Furthermore, the technological advancements of Photovoltaic cells have created a path for cost-effective strategies, job creation and economic growth, energy independence and various environmental benefits.

The future of Photovoltaic cells continues to dominate the solar industry with the increased efficiency, integrating energy storage, and expansion of the market in different continents (Asia, Africa, and America). Also, innovative applications such as building-integrated photovoltaics (BIPV) and transparent windows motivate the PV industry to prioritize sustainable and cleaner product lifecycles.

Ray is an avid reader and writer with over 25 years of experience serving various domestic and multinational private and public energy companies in the USA.