The solar cell evolution first started with the photovoltaic effect discovered by French physicist Alexandre Edmond Becquerel in 1839. The first solar panel created had an efficiency of 6% during the 1950s.

Further, many design innovations played a very important role in improving the solar panel’s performance. The design of classic flat panels evolved into a variety of form factors that include multi-junction cells, concentrator photovoltaics, and bifacial panels.

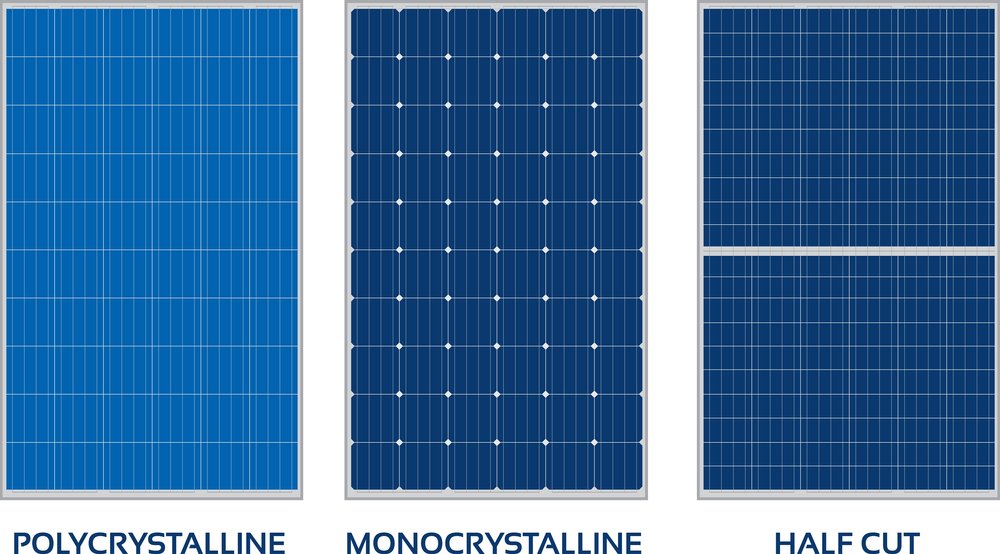

Half-cut solar cells are the traditional silicon solar cells, cut into half using a laser to increase the solar power systems’ performance and efficiency. It is named Half-cut, also known as half-cells because they are created by splitting a traditional solar cell into 2 small cells.

These Half-cut solar cells have a great significant value in the solar industry as they have reduced the power losses in standard PV modules and achieved higher efficiency. Also, they allow a solar panel to be divided into 2 separate units, allowing one half to function with full performance even if another half gets shaded.

In 2014, REC Solar pioneered a design that became the manufacturing industry’s standard as Half-cut solar technology for PV modules and remains one of the latest and best attempts in the solar industry.

Before knowing whether Half Cut Solar Panels are worth buying, you must understand the concept of what are Half-Cut Solar Cells, its working, advantages and disadvantages. Also, you must be aware of its other features such as Higher Efficiency, Improved Shade Tolerance, Greater Wattage and Enhanced Durability. So that, you will have an idea of the High Cost of Manufacturing, which also comes with high Chances of Cell-Inherent Defects.

Let us keep you equipped with information and details, including the differences between Half-Cut vs. Traditional Solar Cells. If you decide to buy, then you must be aware of which companies produce half-cut solar panels in the USA.

What are Half-Cut Solar Cells?

The very first half-cut cell solar panels were discovered in the year 2014 by REC Solar, whose primary goal was to double solar panel energy production.

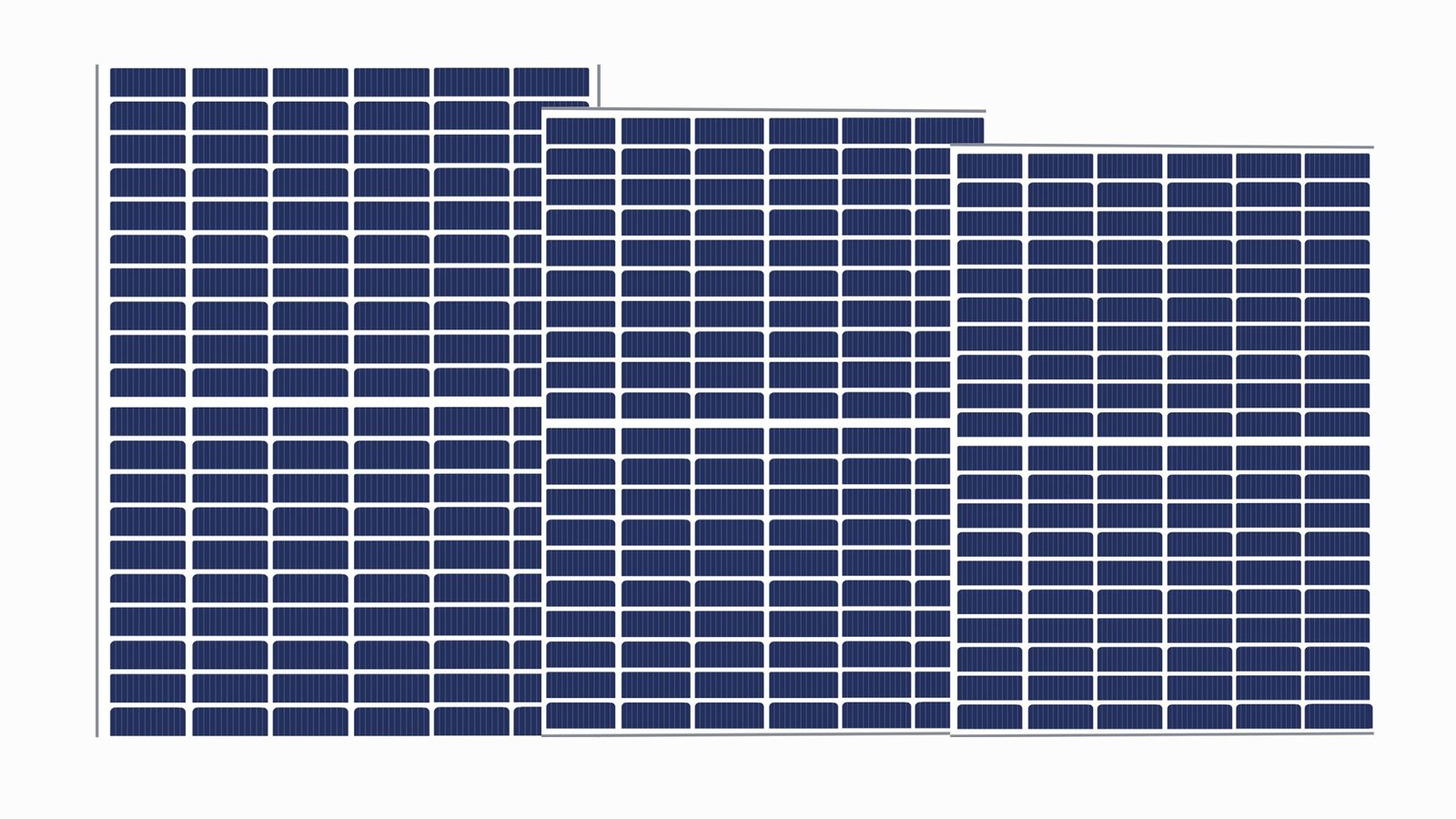

Generally, Half-cut solar panels increase the number of cells to 115 or 145 cells per module, which results in lowered electrical resistance, and improved efficiency. Also, these half-cut panels are good at resisting the shade effects better than compared to standard solar panels.

Half-cut cells added in solar panels like the PERC and Bifacial solar panels include significant benefits including — a boost in power output, low power loss, and improved shading tolerance.

The design difference is observed as Half-cut technology has a smaller cell size in comparison to the traditional designs but offers superior performance with innovative wiring. There are so many different types of solar panels you should also know.

How Do Half-Cut Solar Cells Work?

Half-cut solar cell technology works by offering many beneficial factors and being a promising alternative to traditional solar panels, with its excellent efficiency, production, and performance. The standard manufacturing process of Half-cut solar cells begins with the development of large silicon wafers. Further, it undergoes a few chemical processes to set up the p-n junction, the basic structure for converting sunlight into electricity.

The Production Differentiation lies where manufacturers use laser technologies to perfectly split the larger wafers into small rectangular cells, requiring higher-end equipment and technical knowledge compared to traditional solar cells. However, the latter process is similar to traditional methods, where these half-cut cells are joined together and arranged within the solar panel frame.

The Operational Principles of Half-cut solar cells stick to the same basic principles of traditional solar cells including — The photovoltaic Effect where sunlight passes through the silicon cells, excites the electrons and generates electric current. It also uses Series and Parallel Connections, where each of the cells is connected in series and parallel arrangement to improve the panel’s overall voltage and current output.

Also, cutting cells into halves impacts their performance and efficiency by the enhanced shading tolerance where even if one portion of the panel experiences shade, the other unshaded half will still be able to generate electricity. It minimizes the overall power loss compared to traditional panels, where shade can greatly impact the entire panel’s output.

Advantages of Half-Cut Solar Cells

Half-cut solar cells have numerous advantages compared to the traditional solar cells, including:

- Improved performance of panels using

- Increases panel efficiencies

- Reduced generated current from each cell

- Lowers resistive losses.

- Higher shade tolerance

- NO or Minimal energy loss

- Improved low-light performance

- Compact design

- Lesser prone to cracks

- Minimized hotspot temperature

Higher Efficiency

The reduced size of half-cut solar cells ultimately leads to improved performance and efficiency by lowering 75% of electrical loss and increases 3.6% of CTM power. It also increases module resistance in response to partial shading.

Splitting the cell into half will reduce the flowing current in each cell, which impacts resistive power losses directly proportional to the square of the current (I^2R).

By reducing the cell size, the length of the current path is shortened, leading to lesser resistance and improved efficiency.

Also, Enhanced Thermal Management is observed where tiny cells have a large surface area to volume ratio compared to their larger counterparts. However, this design is beneficial as it allows for improved heat dissipation rate.

If there is any efficiency gain from 1.5%-3%, the credit goes to the reduced size of cells. The combination of improved shade tolerance and considerably higher power output is very beneficial during non-ideal conditions. There are also a lot more important things about solar panel efficiency you should know.

Improved Shade Tolerance

Traditional solar panels if partially shaded are easily sensitive to excess power loss because the entire module’s current flow interferes by shading just one cell. However, half-cut cells have fixed this issue by splitting those traditional cells into 2 halves, where each cell produces half the current.

Also, the reduced shading impact is observed due to the design because only that particular affected half experiences power loss. Meanwhile, the unshaded half continues producing power. As a result, half-cut cells solar panels provide more favourable shade tolerance, maintaining higher energy production during partial shade conditions.

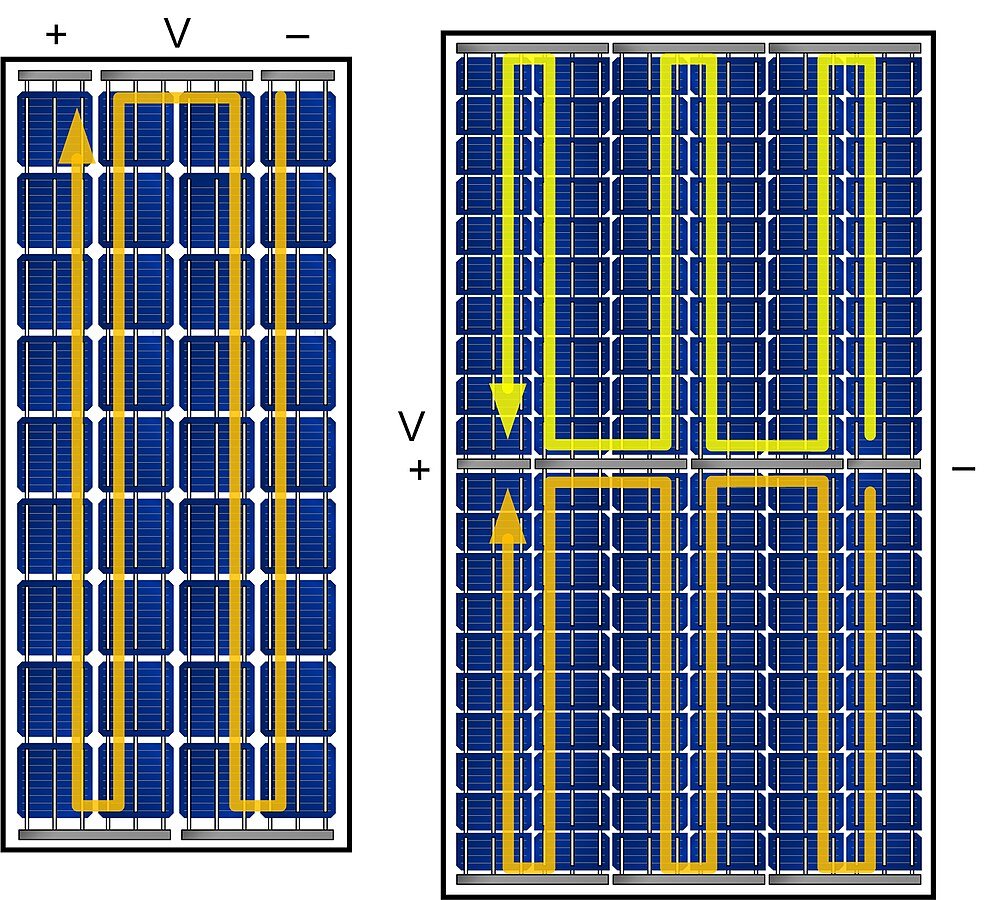

In traditional solar panels, it is observed that the cells are wired in series, where the generated current in each cell flows across the entire panel. However, in half-cut solar panels, those standard cells are split which are further wired in parallel pairs.

However, rather than the current of all cells being dependent on one another, it is better to have a shared current between pairs of cells. Therefore, the shading impact on energy production is reduced, and it leads to improved performance under minimally shaded conditions.

Greater Wattage

Half-cut solar panels tend to deliver greater wattage compared to traditional panels with the same number of cells because reducing cell size into 2 halves decreases resistive losses and improves efficiency.

Moreover, these half-cut panels are capable of capturing excess sunlight due to tiny individual cells, which leads to a high power output. As a result of wattage comparison, half-cut solar panels are more likely to produce greater energy generation compared to traditional panels.

Enhanced Durability

Though half-cut cells are smaller, they come with built-in benefits in terms of durability and go through less mechanical stress compared to the big traditional cells. One of the benefits is that they are much less prone to cracking, as they have a shorter distance for thermal expansion and contraction during extremely high-temperature fluctuations.

Less Severe Hotspots

Hotspots are formed at times when one or more regions of a solar panel are experiencing higher temperatures, usually due to shading or cell malfunctions. As a result, a particular amount of heat can continue to damage the affected area and create a never-ending cycle.

Half-cut solar panels are much less prone to severe hot spots because of their design and wiring configuration. Since half-cut cells are wired in parallel pairs, the shading impact on the individual cells is minimized.

Also, it reduces hotspot occurrences due to the smaller size of each cell, allowing more consistent and distributed heat dissipation across the panel and reducing the hotspot risks. As a result, half-cut solar panels offer top-notch thermal performance and are less prone to the harmful effects of targeted heating.

Reduced resistive losses

Typically, resistive losses are caused to occur when the electricity comes up against resistance within a solar panel while it is travelling through the conductors, such as wires and ribbons. Similarly to the effect of friction, this resistance discharges some energy as heat, resulting in a very slight efficiency loss.

Half-cut solar cells efficiently reduce resistive losses, by decreasing half the current passing through each cell because fewer electrons are travelling across small conductive paths.

Moreover, the half-cut cells’ parallel wiring configuration further reduces resistive losses by spreading the current a bit evenly across the panel. As a result, half-cut solar panels achieve greater efficiency and a decrease in resistive losses compared to traditional panels, especially during severe operating conditions.

Disadvantages of Half-Cut Solar Cells

Half-cut solar cells have a few disadvantages, mentioned as follows:

- Half-cut solar cells are typically more costly than the traditional standard solar panels due to the difficulties in their making process.

- The cell-cutting process into half and soldering together usually takes a lot of time, energy, and machinery.

- Half-cut solar cells deliver higher-wattage than traditional standard panels.

- Although Half-cut solar cells generate only half the current of a standard cell.

- Reduces resistive losses while attaching solar modules.

High Cost of Manufacturing

Half-cut cell solar panels deliver a higher cost of manufacturing than traditional panels due to their complex production process.

The cutting process and individual cell wiring include a few steps that make the entire process very expensive, such as — splitting solar cells using a laser is a very delicate process which requires high-end equipment and highly skilled employees.

Bioreactors specifically designed for cell development, advanced filtration systems, and the use of cryopreservation tools lead to expensive initial and recurring costs.

The cost of Half-cut solar panels is 0.6-1.2% more expensive than whole-cell modules. Also, their making requires nearly two times the average number of cells, affecting the overall cost.

High Chances of Cell-Inherent Defects

During the manufacturing process, when the cells are cut in half, there are chances for inbuilt defects to arise which compromises their reliability and performance.

The first and foremost primary concerns are structural damage and contamination. Advanced cutting techniques, carrying out manufacturing processes in a clean room, following thorough quality control checks.

Therefore, Half-cut solar cells have much greater chances of producing defective cells for the reason that solar cell cutting into half means there are two times as many electrically soldered connections. It means that there are double the number of faulty contacts.

Performance Comparison: Half-Cut vs. Traditional Solar Cells

It becomes a tough decision to choose solar panels between half-cut and traditional solar cells as it depends on the following factors to be considered for a long-term investment.

Half-cut cells are initially very expensive because of their complications in manufacturing and high cell count. As the production is scaling up, we could observe that their price point is steadily decreasing. Whereas, traditional cells have a low initial cost because their manufacturing process is simple with just a few components.

These Half-cut cells have more than 20% efficiency, compared to the 14-17% range of traditional cells. Ultimately, it leads to greater power generation per unit area. Also, it requires only a few panels for the same output as required. Meanwhile, traditional cells have low efficiency, leading to reduced power generation. However, it requires more panels to produce the same output as half-cut does.

When it comes to Durability, both the technologies Half-cut solar cells and Traditional solar cells provide excellent durability. It comes with a wonderful lifespan which is more than 25 years and guarantees hardly any degradation over time.

Performance under various conditions differs based on factors such as — shade tolerance in which Half-cut cells perform better and temperature coefficient where both types of cells perform well even in hot climates. However, sometimes the half-cut cells undergo power loss and become slower compared to traditional cells during temperature rise.

According to the study and research reported by the National Renewable Energy Laboratory (NREL), they have found that half-cut cells are capable enough to generate 3% more energy compared to traditional cells under appropriate conditions.

Are Half-Cut Solar Panels Worth It?

Half-cut solar panels are better than traditional solar panels, as they tend to work better, especially when a part of the panel is shaded (For instance: like from a chimney). It maintains reduced power loss inside the panel, which leads to better power output. Also, it lasts longer because of lower operating temperatures.

At the same time, Hal-cut solar panels are not as common panels because of their expensive cost range per watt as compared to other regular panels. Also, it is very hard to find as it is not readily available in all areas.

These half-cut solar panels can benefit certain people for their homes or businesses that have shadows on their roofs. Generally, for people who are looking for the best power output as well as the greatest lifespan, then this would be the best value-for-money panel. Also, areas that have high electricity costs will benefit from half-cut solar panels to maximize power wherever it is important

Which Companies Produce Half-Cut Solar Panels?

Here is a List of companies that sell half-cut solar panels in the USA:

- Jinko Solar

- First Solar

- Mission Solar

- Panasonic

- Auxin Solar

- Qcells

- Silfab

- Solar 4 America

- SolarTech Universal

- Complete Solaria

- Auxin Solar

- Sunpower

Hence, These renowned companies in the USA produce Half-cut solar panels which are better than the traditional standard solar panels in many ways.

Ray is an avid reader and writer with over 25 years of experience serving various domestic and multinational private and public energy companies in the USA.