Solar cells, or photovoltaic cells, are elements that use the photovoltaic effect to convert light energy efficiently into electrical energy. They are a primary component of solar panels that help generate clean, renewable energy from sunlight.

The solar cells evolution brought many technological advancements for improving efficiency and reducing costs. From the very early stages of silicon-based solar cells till the rise of thin-film and multi-junction cells, the solar industry has been continuously developing many new techniques for completely making use of solar energy safely and efficiently.

Heterojunction solar cells (HJT) are a specific type of solar cell, bringing crystalline silicon qualities with thin-film technologies to form a hybrid cell that delivers the best features with top-notch performance.

HJT is a hybrid technology which is well known for its higher efficiency, combining the characteristics of both traditional crystalline solar cells and thin-film solar cells.

Did you know? A type of HJT cell, with an Inbuilt interior Thin-layer (HIT) solar cell structure, was originally developed in 1983 by Japanese scientist and was later brought into the markets by Sanyo/Panasonic.

However, HJT cells were used to improve Solar panels to provide high-efficiency rates with improved performance even at high temperatures. Also, it is capable enough of converting sunlight into electricity using both sides of the panel (bifaciality).

Let us keep you equipped with the heterojunction solar cells’ definition, materials used, structure, manufacturing process, advantages, and disadvantages. Also, we will discuss the HJT technology development, its alternatives, and its future potential.

What are Heterojunction Solar Cells

The term ‘Heterojunction’ regarding solar cells means a junction between 2 different types of silicon, where each of them has its distinctive properties. Heterojunction Solar Cells are well-known for their higher efficiency, with their monofacial modules reaching up to 27% and the bifacial modules exceeding 30%.

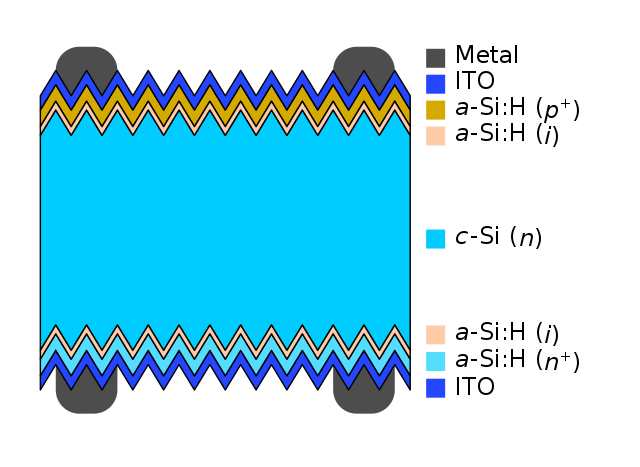

The materials used in Heterojunction solar cells (HJT) include — crystalline silicon (c-Si), amorphous silicon (a-Si), and indium tin oxide (ITO). The reason to prefer these materials is that they merge amorphous silicon’s high absorption properties with crystalline silicon’s excellent charge transmission properties. Also, these materials are capable of capturing a wide range of light wavelengths.

The structure of an HJT solar cell is composed of an N-type monocrystalline silicon wafer in the base, with undoped thin amorphous silicon layers on both sides. This is usually combined with a transparent conductive oxide layer followed by metal conductors to further improve the electrical conductivity.

How are they manufactured?

The manufacturing of HJT cells involves several steps, including — the preparation of monocrystalline silicon wafer, the layering of amorphous silicon layers, and the implantation of conductive oxide layers.

Here are the several steps involved in the manufacturing process of HJT solar cells:

- Cleansing and texturing process of the silicon wafers, preparing them for deposition or layering.

- Amorphous silicon layers are deposited using Plasma Enhanced Chemical Vapour Deposition (PECVD), allowing detailed control of the thin film’s properties.

- Transparent conductive oxide (TCO) is applied to the layer through Physical Vapour Deposition (PVD), thus contributing to the cell’s capability to capture light.

- Metal conductors are added by Screen printing and curing, creating an electrical contact that is required for cell functioning.

PECVD (Plasma Enhanced Chemical Vapour Deposition) is a process that deposits thin films from a gas state to a solid state on a substratum. Performing this process applies the amorphous silicon layers in HJT cells at moderately low temperatures.

PVD (Physical Vapour Deposition) is another deposition method that is used in solar cell manufacturing. It creates a thin film by condensing the desired film material’s vaporized form onto the substrate.

Recent developments in the HJT cell manufacturing process include advanced deposition techniques and the discovery of previously unknown materials/structures to further strengthen efficiency and reduce costs. Also, it includes technological innovations in cell architecture and production methodology, improving reliability. There is a lot more to know about how solar panels are made.

{Video Credit: Hanplast Solar Ukraine}

Advantages of Heterojunction Solar Cells

The advantages of Heterojunction Solar Cells include higher efficiency, low-temperature coefficients, bifaciality, better low-light performance, and lower attenuation of power over time.

Higher Efficiency

Laboratory-level HJT cells achieved more than 27% efficiencies and have the potential to exceed higher efficiencies in future.

HJT cells have higher efficiency because of the heterojunction’s strong charge carrier separation and cell structure’s reduced electronic defects.

The higher efficiency of HJT cells means the capability to generate more power, making them a great choice for applications with limited space, like residential rooftops or embedding into building materials.

Also, these HJT cells are widely utilized in solar shingles, building-integrated photovoltaics (BIPV), and wearable devices for their versatility and higher efficiency.

Low-Temperature Coefficient

The low-temperature coefficient of HJT cells indicates that their performance is not negatively impacted by high temperatures. It makes them extremely well-suited for hot climates, where solar panels get very hot and traditional cells suffer performance loss.

Lower attenuation

Attenuation in solar panels means degradation or reduction of solar panel power output over time. HJT cells have lower attenuation compared to other technologies like PERC cells. As a result, they are capable of maintaining their performance levels for longer periods

Usually, Attenuation affects a solar panel’s long-term performance and reliability, decreasing the amount of electricity production.

Therefore, these HJT cells mitigate attenuation with their design and materials, which are less prone to degradation than compared to those in traditional solar cells.

Better Low-Light Performance

HJT cells are capable of delivering a better low-light performance compared to traditional solar cells, generating more electricity in certain conditions like — early morning, late afternoon, or on cloudy days.

High Bifaciality

High bifaciality refers to light absorption by solar cells and generating electricity using the HJT cells, which are capable of capturing sunlight from both the front and back sides of the panel make it bifacial solar panel.

As these cells have a 93% bifaciality factor, they are very beneficial, especially for utility-scale projects where even the reflection of sunlight from the ground can be taken advantage of for increased energy yield.

In a few cases, the bifaciality factor of HJT cells could be high, with some cells achieving more than 30% efficiency with bifacial arrangements and configurations.

Disadvantages of Heterojunction solar cells

Disadvantages of HJT cells include complex manufacturing processes, and the possibility of less durability compared to traditional cells. Also, there are a few challenges in trying to compete with well-established traditional solar technologies.

Complex Manufacturing Process

The manufacturing process of HJT cells is very complicated compared to traditional solar cells, resulting in higher costs as it demands in-depth knowledge and equipment. However, current research and development are focusing on simplifying these processes and reducing costs.

Efforts to mitigate these challenges include — enhanced manufacturing processes, improved economies of scale, new techniques and optimising existing processes, making them cost-effective.

Less Durable

Generally, HJT cells are durable, but they have a thin and complicated structure and due to some of these design components or materials they become less robust than compared to a few traditional solar cell technologies. Also, these HJT panels are very sensitive to moisture, which can impact their efficiency and longevity.

New Technology

HJT cells will experience problems in competing with well-established technologies like PERC and Topcon because of factors like — market exposure, cost, existing manufacturing environment and equipment. Since HJT cells are a new technology, they face challenges regarding the production scale also.

Development In Heterojunction Technology

The most recent Heterojunction Solar cells (HJT) technological advancements include — material improvements, cell design, and latest layer deposition methodologies. However, there is so much potential for using the HJT cells along with other solar technologies, like the tandem system with perovskites. Also, challenges of cost reduction and increasing production scale have to be addressed in order to improve the adoption.

Therefore, by integrating HJT cells with other solar technologies, creating hybrid systems will benefit from each technological strengths. Also, reducing the complications in manufacturing process, increasing its durability, and decreasing costs are also few challenges that have to be addressed in order to make HJT cells more competitive compared to other cells.

{Video Credit: WAAREE Energies Limited}

What are the alternatives to Heterojunction Solar Cells

The 2 alternatives to HJT cells are PERC (Passivated Emitter Rear Cell) and TopCon (Tunnel Oxide Passivated Contact) solar cells.

PERC and TopCon solar cells possess similarities in terms of higher efficiency and the utilization of crystalline silicon. However, they have differences in their respective manufacturing procedures, cost, and other performance factors. For instance, TopCon cells have efficiencies ranging in between the range of PERC and HJT cells, so it might act as a bridge between these two technologies.

However, they differ in their characteristic materials, structures, and how capable they are in managing light absorption. Also, they have a good charge carrier system to operate at high efficiency.

In conclusion, heterojunction solar cells serve as a major advancement in solar technology, resulting in high efficiency, low-temperature coefficients, and excellent low-light performance. Despite many advantages of HJT, there are complicated challenges in terms of manufacturing and durability. As the technology is developing constantly, the challenges might be rectified in future, providing sustainable, cost-effective and environment friendly energy solution in the future.

Ray is an avid reader and writer with over 25 years of experience serving various domestic and multinational private and public energy companies in the USA.